Directional/complex wells

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

This paper presents a study of trapped-torque incidents during drillpipe connection, highlighting contributing factors and root causes and proposing prevention and mitigation measures for these transient events.

In this study, a method was developed to analyze the effects of drilling through transitions on bit-cutting structures and construct an ideal drilling strategy using a detailed drilling model.

-

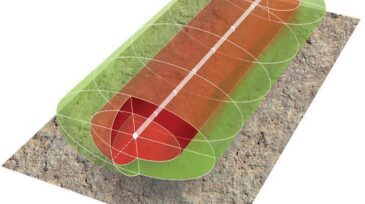

Wellbore position is computed from survey measurements taken by a measurement-while-drilling (MWD) tool in the bottomhole assembly (BHA).

-

Saudi Aramco operates a large offshore oilfield development that has driven achievements in multilateral and extended-reach directional wells.

-

Eight of the world’s 10 longest wells have been drilled by ExxonMobil as operator of the Sakhalin-1 project in Russia.

-

The development of multilateral wells and long-reach wells has become important to maximizing recovery for many fields. These technologies are often applied in offshore environments, where large reservoir areas are drained from one or more platforms.

-

This paper discusses the first multilateral well with a Level-4 junction combined with an inflow-control device (ICD) planned, designed, and drilled in the Upper Burgan reservoir of Raudhatain field, north Kuwait.

-

The only wells that are straight or follow a smooth curve are in the pictures in well plans. Real wellbores are shaped by the mechanics of directional drilling tools, the skills and attention of drillers, the force of gravity, and the path followed by hydrocarbon-rich seams of rock.

-

While rotary-steerable systems (RSSs) dominate the offshore directional-drilling markets, the land-based markets are still dominated by conventional directional-drilling tools. This paper presents a new RSS that is being designed and tested specifically for the onshore markets.

-

This paper offers insight into an integrated effort at combining analytical information, numerical well-test models, and geological evidence to explain the reservoir behavior observed in the Huntington field.

-

For thin-oil-rim reservoirs, well placement, well type, well path, and the completion methods must be evaluated with close integration of key reservoir and production-engineering considerations.

-

This paper gives the recommended MSF horizontal-well spacing for several development scenarios in Saudi Arabian gas-reservoir environments.