Drilling

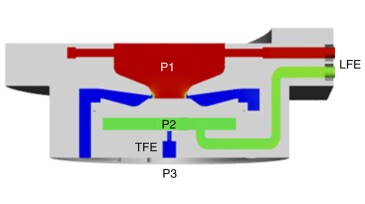

The paper describes a multientry multistage fracturing technology developed to enable longer laterals, increase stage counts, improve stimulation efficiencies, and derisk operations.

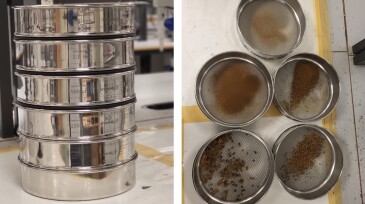

This paper provides an account of the design, implementation, and operational insights from an enhanced geothermal system proppant stimulation targeting a volcanic, dry rock setting with an approximately 330°C bottomhole temperature.

This study evaluates the feasibility of drilling a closed-loop, unconventional geothermal system in the Pannonian Basin basement of Romania.

-

This case study investigates the reasoning behind the solidification of barite behind the casing with the aim of developing solutions for efficient casing removal and the potential use of settled barite as a barrier material.

-

Driller expects $370 million, all-stock transaction to close in early 2025.

-

We’re thrilled to announce the launch of the 2025 SPE/JPT Drilling and Hydraulic Fracturing Technology Review. This exclusive, official publication will be distributed at three major SPE industry events.

-

A fundamental research study is conducted to confirm the potential usefulness of chelating agents in dispersing settled barite, emphasize the complex nature of the factors that control this process, and provide a solid basis for future studies aimed at optimizing dispersion methods in industrial applications.

-

The agreement formalizes JV ownership of Turnwell Industries which ADNOC Drilling created to manage a $1.7 billion unconventional drilling contract awarded in May.

-

This paper describes the qualification of a multilayer, open-cell matrix polymer system for the first horizontal deployment in an offshore gas well.

-

This paper delves into the evolving landscape of drilling automation, emphasizing the imperative for these systems to go beyond novelty and deliver quantifiable financial value.

-

This paper describes installation of autonomous inflow control valves in the Bretaña Norte field in Peru, enabling effective water control even though the trial well was placed in the flank, close to the oil/water contact.

-

This update highlights efforts to electrify oil and gas assets and deliver clean energy to remote, underserved communities. But the big question remains: Can we really achieve net zero emissions by 2050?

-

These papers underscore the need for strategic adaptation of automation systems to the specific challenges of offshore environments. The success of predictive machine learning in this context depends on its ability to offer measurable financial benefits, improve safety, and drive operational efficiency.