Drilling

This paper provides an account of the design, implementation, and operational insights from an enhanced geothermal system proppant stimulation targeting a volcanic, dry rock setting with an approximately 330°C bottomhole temperature.

This study evaluates the feasibility of drilling a closed-loop, unconventional geothermal system in the Pannonian Basin basement of Romania.

The paper describes a multientry multistage fracturing technology developed to enable longer laterals, increase stage counts, improve stimulation efficiencies, and derisk operations.

-

The paper highlights two case studies to illustrate successful development of marginal prospects to unlock remaining potential.

-

The authors describe a study in which leakage-rate modeling was performed to identify and evaluate the associated risks for designing a remedial action plan to safeguard a CO2 storage site.

-

The authors write that polymeric additives are effective in the design of complex systems to house important chemical reagents under challenging conditions.

-

Against a backdrop of global uncertainty and challenging economics, well integrity subject-matter experts have continued to prioritize human and environmental safety in production while pivoting their skills toward areas of growing importance such as carbon capture and sequestration. New technologies and simulation methods have allowed the authors of the three SPE pap…

-

This paper examines current practices and developing trends in well construction and describes an alternative cementless approach to the discipline.

-

Norwegian operator plans to drill 50% more exploration wells in Norway during 2022 than it did in 2021.

-

Totally automated drilling today looks like a robot doing all the heavy lifting on a drilling floor. By 2025, there may no longer be anything surprising about it.

-

Well construction must always be executed safely at reduced operational costs, while ensuring appropriate wellbore quality and placement, per asset team requirements. Consequently, analysis of drilling efficiency, a critical performance indicator, has moved from maximizing rate of penetration to improving cycle time.

-

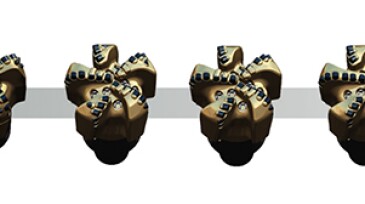

A supervised machine-learning algorithm is developed to classify drilling parameters that increase rate of penetration and bit endurance for use in unconventional fields in Australia.

-

The failure of the Raptor rig to drill its first-ever well offers a short history of the challenges that came with creating the first automated drilling rig.