Drilling

The paper describes a multientry multistage fracturing technology developed to enable longer laterals, increase stage counts, improve stimulation efficiencies, and derisk operations.

This paper provides an account of the design, implementation, and operational insights from an enhanced geothermal system proppant stimulation targeting a volcanic, dry rock setting with an approximately 330°C bottomhole temperature.

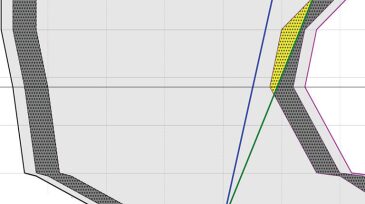

This study evaluates the feasibility of drilling a closed-loop, unconventional geothermal system in the Pannonian Basin basement of Romania.

-

The hybrid power technology cuts fuel consumption and boosts the dynamically positioned rig’s station-keeping reliability, the drilling contractor says.

-

Measured-pressure approaches have offered much promise for some time but have been slow to reach widespread application. A spate of technical developments, deployments, trials, and applications, however, recently has pushed measured-pressure drilling and its nuanced variants to their full potential.

-

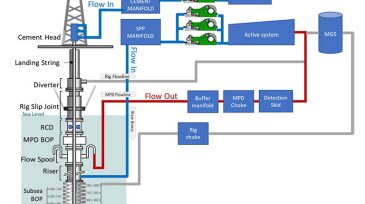

This paper presents lessons learned regarding design, testing, and installation of a completely integrated managed-pressure-drilling (MPD) control system on a deepwater drilling rig.

-

This paper presents the design considerations, methodology, and results of two deepwater MPC operations conducted to cement production casing strings within a target operating window of approximately three-tenths of a pound.

-

This work focuses on the development of specific methodologies to support managed-pressure-dilling (MPD) operations implemented on real-time diagnostic software.

-

ConocoPhillips has pulled out of the much-hyped Louisiana Austin Chalk play after the company’s test wells yielded a gusher of water. Meanwhile, an Australian operator flying under the radar continues to pursue the adjacent-but-even-more-challenging Tuscaloosa Marine Shale.

-

SponsoredIn oil and gas offices around the globe, the term digitalization prompts a range of responses. This white paper outlines a pragmatic approach to digitalization for oil and gas operators, with a focus on drilling and completion.

-

The Yakaar-2 appraisal well encountered 30 m of net gas pay in a similar high-quality Cenomanian reservoir as the Yakaar-1 discovery well drilled in 2017.

-

ExxonMobil has now made 14 discoveries offshore Guyana, while Tullow's announcement of its second find in the basin comes just a month after reporting its first.

-

Not all friction reducers are created equal. With dozens of varieties on the market, industry research suggests that oil and gas companies be choosy.