Drilling

Oil and gas companies drilled 75 “high-impact” wells in 2024, representing 5.2 billion BOE.

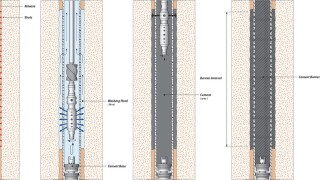

This paper presents a comprehensive literature review of perforate, wash, and cement techniques that compares new methods with traditional ones and uses field cases and computational fluid dynamics to find the most cost- and time-effective practices without sacrificing safety.

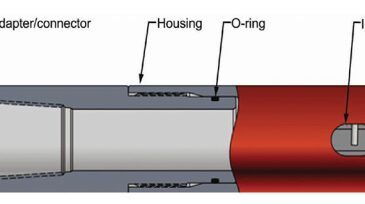

The authors of this paper describe a method of stimulating a multizone hydrocarbon-producing well wherein a tool is deployed downhole by wireline to generate acid vapor at a target depth, allowing each interval to be treated uniquely.

-

Telling executives that the cost per foot drilled is down is not going to convince them that drilling is getting more efficient. That requires translating drilling measures into the language of corporate budgeters.

-

Geothermal power offers enormous potential—an inexhaustible supply heat to drive huge electric plants around the clock—but that extreme heat can quickly kill conventional hardware, which led to something new.

-

Drilling customers would like to be able to buy the hardware they need from the vendor of their choice and plug it into an automated system, but the companies creating the control systems say they can not afford to do that.

-

This paper presents the planning and execution of a matrix-stimulation pilot project in the heavy-oil Chichimene Field in Colombia.

-

Drilling and completion expenditure and activity is projected to show multiyear double-digit growth from 2018–2022 despite a flattening of rig count increases.

-

Phrases such as “dawn of the new age of the oil and gas industry,” and “the fourth industrial revolution” echoed through halls of SPE events in 2017 and into the new year, with rapid advancements in big data management, digital connectivity, and high-performance computing.

-

This paper details the operational effects of closed-loop drilling to demonstrate its ability to yield operational-process-safety improvements and cost savings over conventional methods.

-

This paper discusses the technical challenges related to implementing a rigsite, real-time drilling advisory system and current solutions to these challenges.

-

An operator partnered with the drilling-automation research group at The University of Texas at Austin to develop a work flow for big-data analysis and visualization. The objectives were to maximize the value derived from data, establish an analysis toolkit, and train students on data analytics.

-

Considering the significant weight of drilling costs in upstream ventures, saving even a few hours of drilling could lead to substantial cost savings on the overall capital expenditures (Capex). Thanks to the big data revolution, cost optimization still has strong potential in drilling operations.