Drilling

Oil and gas companies drilled 75 “high-impact” wells in 2024, representing 5.2 billion BOE.

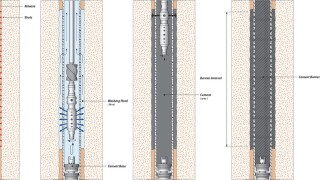

This paper presents a comprehensive literature review of perforate, wash, and cement techniques that compares new methods with traditional ones and uses field cases and computational fluid dynamics to find the most cost- and time-effective practices without sacrificing safety.

The authors of this paper describe a method of stimulating a multizone hydrocarbon-producing well wherein a tool is deployed downhole by wireline to generate acid vapor at a target depth, allowing each interval to be treated uniquely.

-

A new process system compatible with all types of drilling rigs is opening the door to wider adoption of drilling automation in North America’s shale sector.

-

The offshore drilling sector has taken a step towards consolidating an oversupplied market and Ensco will emerge from this most recent deal as the owner of the largest combined fleet of floaters and jackups.

-

By creating a different sort of partnership for a drilling project with close cooperation and greater efficiency built into every detail, including the contracts, Statoil was able to halve the cost of drilling eight wells at its Johan Sverdrup field.

-

Along its journey to full-automation, the US drilling sector is facing a series of important crossroads that will determine what the so-called “rig of the future” really will be.

-

This paper presents a critical review of the recent literature to determine the status of research and development and field application of nanotechnology in the oil field.

-

The quick turnaround times and low-risk nature of shale developments need to be replicated in the deepwater business, according to the CEO of Murphy Oil.

-

Multilateral wells with smart completions controlled by different flow-control technologies offer great operational flexibility, with each lateral able to be operated and optimized independently.

-

This paper demonstrates how the latest generation of connections has been tested and validated to extreme loads before being installed in the wellbore.

-

A North Sea field development included installation of long 4½-in. completion liners in the horizontal reservoir sections of each well. To minimize overall risk, the operator planned to use managed-pressure drilling (MPD).

-

A field well was designed, built, and used to demonstrate the concept of real-time monitoring of the flow of drilling mud and smart cement and the hardening of the cement in place.