Drilling

Oil and gas companies drilled 75 “high-impact” wells in 2024, representing 5.2 billion BOE.

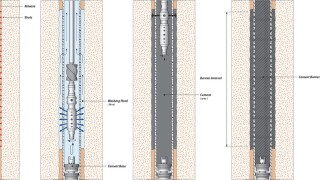

This paper presents a comprehensive literature review of perforate, wash, and cement techniques that compares new methods with traditional ones and uses field cases and computational fluid dynamics to find the most cost- and time-effective practices without sacrificing safety.

The authors of this paper describe a method of stimulating a multizone hydrocarbon-producing well wherein a tool is deployed downhole by wireline to generate acid vapor at a target depth, allowing each interval to be treated uniquely.

-

An analysis studied whether a well's toe could be affecting the production performance.

-

How do mooring systems reduce risks of hurricane damage to mobile offshore drilling units?

-

As systems automation becomes more widespread in drilling, simulators are required to plan, train rig crews, and monitor real-time operations.

-

Although early inflow control devices and intelligent completions (ICs) were introduced almost 20 years ago, completion technology has not kept pace with advancements in drilling technology.

-

A long-time energy industry executive and chemical engineer has built a new water treatment system that he says can increase recovery rates from shale wells without using chemicals and will recycle all the water used in the process.

-

As the drilling industry improves its efforts to capture drilling operation activities in real time, it has generated a significant amount of data that drilling engineers cannot process on their own.

-

This paper shows how automation reduces invisible lost time and allows drillers to focus on other activities while repetitive tasks are controlled by software.

-

To accelerate learning, an operator deployed a real-time, closed-loop downhole automation system (DHAS) in conjunction with wired drillpipe in the 8¾-in.-hole section.

-

This paper presents the LCDSS and elaborates on the use of it in the preparation and training phase and the operational phase, including forecasting.

-

In the Eagle Ford, an integrated approach to engineering and operations was key to optimize performance and improve understanding of the area.