Drilling

The agreement focuses on improving operational efficiency and consistency through advanced digital tools and real-time data integration.

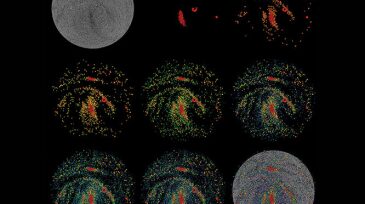

An innovative approach uses a random-forest-based framework to link logging-while-drilling and multifrequencey seismic data to enable dynamic updates to lithology parameter predictions, enhancing efficiency and robustness of geosteering applications.

Oil and gas companies drilled 75 “high-impact” wells in 2024, representing 5.2 billion BOE.

-

In order to avoid some of the detrimental effects of formation damage, a key aspect is laboratory testing of representative core material under representative downhole conditions.

-

The paper presents a new approach that uses X-ray-microcomputed-tomography (micro-CT) scanning to produce high-resolution data of entire core samples.

-

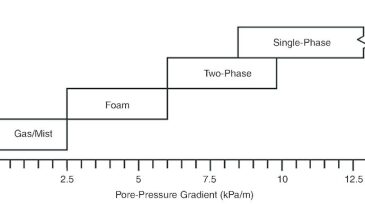

Air drilling has become popular in the Marcellus and Utica shale reservoirs because of its higher rate of penetration (ROP) and less resulting formation damage.

-

Approximately one-half of all offshore conventional oil and gas resources are known or thought to be undrillable with conventional, open-to-atmosphere circulating fluids systems for safety, economic, and/or technical reasons.

-

An ongoing research project started nearly 3 years ago by the US Department of Energy’s National Energy Technology Laboratory (NETL) is shedding new light on what really happens to foamed cement as it is pumped deep down offshore wells during completions.

-

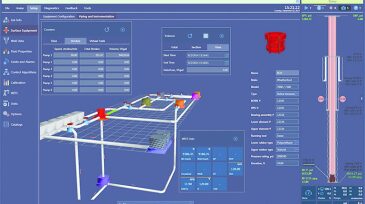

This is an update on several managed-pressure drilling (MPD) technologies and downhole drilling performance-enhancing tools in use onshore and is the first of a two-part series. The second article on offshore MPD technologies will appear in the February issue of JPT.

-

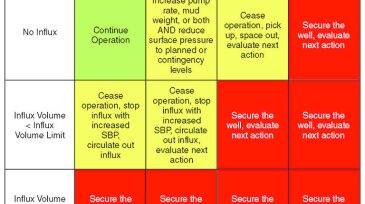

A scientist hired by federal regulators to look for ways to reduce the risk of well blowouts said it is time for the oil and gas industry to treat kicks taken while drilling the same way doctors treat heart attacks.

-

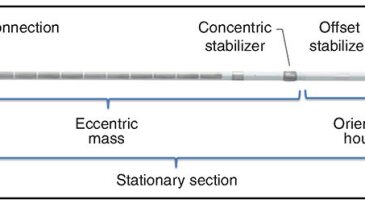

A 100% fully mechanical rotary-steerable tool has been developed specifically for the high-volume drilling market, providing full 3D directional control while under full rotation of the drillstring from surface.

-

The recent introduction of a new rolling-cutter polycrystalline-diamond-compact (PDC) bit that uses 360° of the diamond edge has delivered positive results in field trials.

-

Conventional drilling through lower intermediate intervals in the southern portion of the Alpine field on Alaska’s North Slope has posed significant challenges.