MPD/UBD

This paper reviews the successful application of a mud-cooling and managed-pressure-drilling system in a high-pressure/high-temperature well to explore the potential of a Mesozoic carbonate platform in the Nile Delta of Egypt.

Managed-pressure drilling has been associated as a technology used only on problematic wells and only as a last resort. However, when integrated at the beginning of operations as part of a comprehensive well plan, it becomes a performance-enhancing solution for any type of well classification, including development, directional, multilaterals, and horizontals.

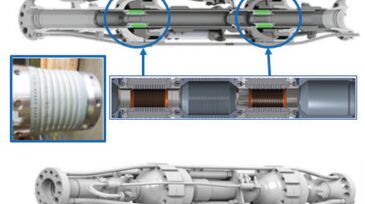

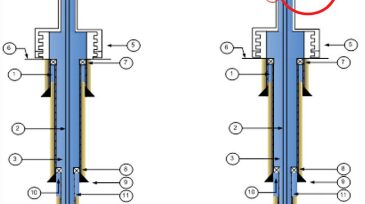

This paper describes the path to implementation of full casing rotation during primary cementing jobs.

-

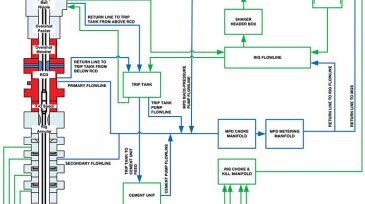

This paper describes how a technique known as applied-surface-backpressure managed-pressure drilling (ASBP-MPD) can alleviate the limitations of conventional deepwater well control.

-

The complete paper describes a recent directional coiled-tubing drilling (DCTD) job completed for an independent operator in the Appalachian Basin.

-

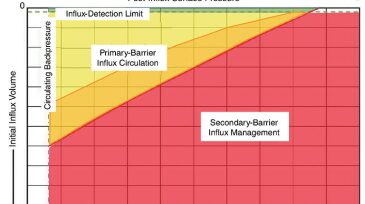

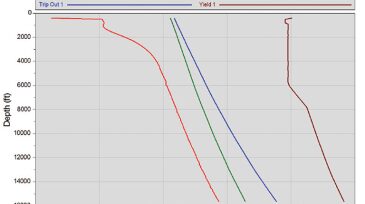

The influx-management-envelope (IME) concept is an advanced, innovative way to assess influx conditions in managed-pressure-drilling (MPD) operations, offering an improved tool for the decision-making process.

-

An early commitment to integrate MPD into an HP/HT drilling operation can make MPD more than just an enabling tool and turn it into a performance tool that offers significant operational benefits.

-

An early commitment to integrate MPD into an HP/HT drilling operation can make MPD more than just an enabling tool and turn it into a performance tool that offers significant operational benefits.

-

This paper details the operational effects of closed-loop drilling to demonstrate its ability to yield operational-process-safety improvements and cost savings over conventional methods.

-

Managed-pressure drilling (MPD) challenges the conventional drilling paradigm, along with drilling-contractor and operator policies and standards. Conventional drilling practices for connections, flow checks, tripping, and well control have been long understood and standardized.

-

In the past, most wells have been drilled using conventional methods, but the landscape is changing as economic pressures have forced the drilling industry to refocus.

-

One common issue among operators in determining whether to install a managed-pressure-drilling (MPD) system for a campaign is the significant upfront cost.

-

The unique properties of deepwater formations pose significant challenges to the capabilities of conventional drilling rigs. Using automated drilling equipment, including MPD, efficiency and cost savings can accompany safety.