Sand management/control

Aurora Innovation and Detmar Logistics have inked a deal for 30 autonomous trucks that will begin hauling sand in the region next year.

This paper describes an automated workflow that helps mitigate sanding caused by excessive drawdown by determining the minimum tubinghead pressure.

As reservoirs become more complex and economics tighter, the industry is shifting toward more-adaptive, data-informed, and targeted solutions. New research highlights innovative solutions that not only address technical limitations in existing designs but also enhance decision-making through digitalization and cross-disciplinary integration. The papers highlighted her…

-

The trend in fracturing designs has been longer stages with more perforation clusters, which save time and money. But there are a couple of companies testing whether shorter is better for production.

-

The first long-haul overland conveyor system to deliver proppant is under construction in the Permian Basin.

-

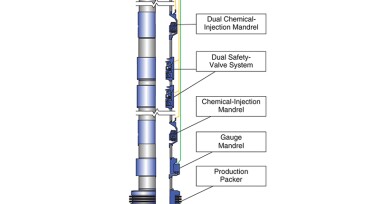

This paper describes an intelligent completion design installed in two deepwater wells with dual-zone stack-pack sand-control lower completions and the installation of an intermediate string to isolate the reservoir in each zone.

-

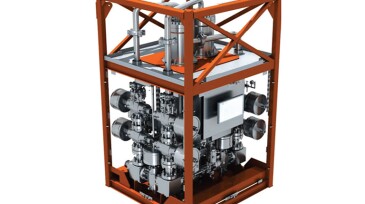

Over 1,000 hours of remotely monitored continuous production was achieved on an unmanned platform—a first for standalone offshore solids management in the North Sea.

-

This paper presents field cases of a rigless wireline logging technique that accurately locates sources of water production in cased wells with standalone sand screens in an offshore field in the Caspian Sea.

-

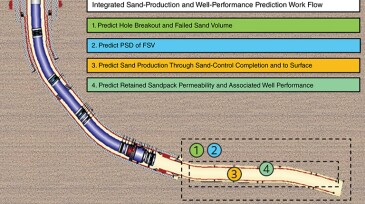

This paper presents a physics-based approach to predict sand production for various reservoir and completion types, explored through a case study of recent production wells in a sandstone reservoir development.

-

This paper describes sand-control design and execution techniques applied to four high-rate gas wells in a deepwater environment.

-

This paper discusses novel acoustic techniques used to identify productive zones and areas of sand production in a well with a sanding event.

-

This paper highlights solids-management technologies that are currently available and still in use topside (some of which are potentially outdated).

-

SponsoredCase study on how a Marcellus operator was able to recover 99%+ of frac sand in high flowrate wells using advanced cyclone technology.