Sand management/control

Aurora Innovation and Detmar Logistics have inked a deal for 30 autonomous trucks that will begin hauling sand in the region next year.

This paper describes an automated workflow that helps mitigate sanding caused by excessive drawdown by determining the minimum tubinghead pressure.

As reservoirs become more complex and economics tighter, the industry is shifting toward more-adaptive, data-informed, and targeted solutions. New research highlights innovative solutions that not only address technical limitations in existing designs but also enhance decision-making through digitalization and cross-disciplinary integration. The papers highlighted her…

-

Drilling longer wells, increasing the number of fracture stages, and completing multiple zones in complex stacked reservoirs, along with optimizing multilateral wells with sand control to enable long laterals in stacked reservoirs, have emerged as key focuses of the industry.

-

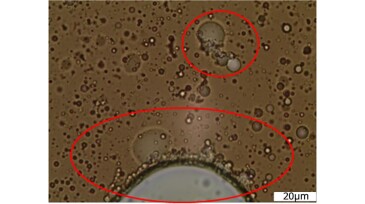

The authors of this paper study the effect of solids particles on oil/water separators and on produced-water treatment.

-

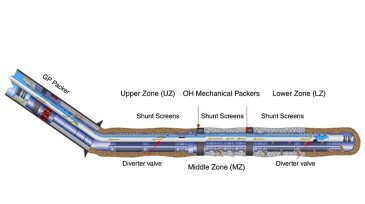

This paper presents the completion strategy implemented in an intelligent well completed in Malaysian deepwater Block K.

-

To avoid costly interventions like sidetracking or wellbore abandonment, a check-valve system was installed near the sandface within three injector wells which prevented the mobilization of fines from the reservoir into the wellbore by stopping backflow.

-

This paper outlines issues to be resolved during facility design and provides guidelines, calculations, and examples for sand-handling steps to be implemented after separation.

-

The authors of this paper describe a coating designed for enhanced erosion resistance for standard wire-wrapped screens that consists of ceramic or hard metal applied by plasma spraying.

-

The authors of this paper describe a project in which retrofitted autonomous inflow control devices were deployed successfully in a field to minimize water production and maximize oil recovery.

-

With the higher adaptation of flow-control devices in recent years to improve flow segmentation and reduce the premature failure of sand control because of highly localized flow, flow-control-device implementation is becoming an integral part of sand-management strategy.

-

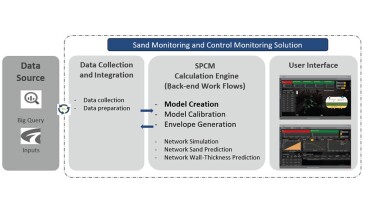

The authors of this paper propose an automated approach to sand prediction and control monitoring that improved operational efficiency by reducing time spent on manual analysis and the decision-making process in a Myanmar field.

-

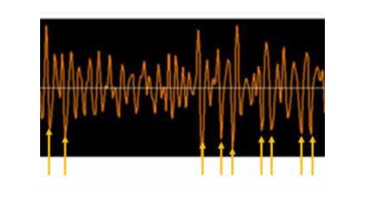

This paper discusses tools and techniques used to localize a tubing leak in a horizontally completed multilateral well, identifying the bore responsible for sand production and providing relative sand quantification at differing flow rates.