Offshore/subsea systems

The awards build on Tenaris’ role in earlier phases of the ultradeepwater Black Sea project.

An earlier deal to double Israel’s gas exports to Egypt led to approval of Leviathan’s Phase 1B expansion by guaranteeing long-term cash flow to finance the project.

Marking a major milestone as the Gulf of Mexico’s second 20,000-psi deepwater development, the project underscores how advanced high-pressure technology, management of flow challenges, and the floating production system’s role as a regional hub are helping open the door to more Inboard Wilcox development.

-

Hurricane Energy is still on pace for first oil in 2019 for the Lancaster field, which may lead to more significant development in the UK North Sea.

-

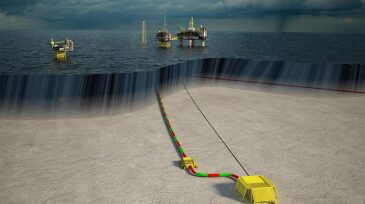

The steel pipe manufacturer agrees to deliver outer pipes for pipe-in-pipe flowlines for a pair of recently-announced Aker BP projects in the Norwegian Sea.

-

Completion of the umbilicals system marks another step toward startup for the Total-operated ultradeepwater development offshore Angola.

-

Offshore project execution enhancement ideas are highlighted for debottlenecking, gas-hydrate-induced pipeline vibration, and the design of subsea systems for efficient startup.

-

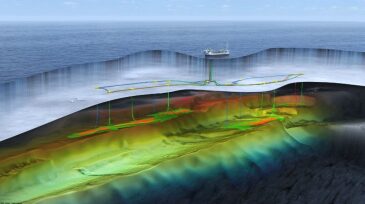

The workflow aims to reduce the startup time of a subsea production system (SPS). A dynamic integrated model is used to adjust the scheduled SPS startup time. The model evaluates the dynamic simulation response of a large field startup by integrating a reservoir- and gathering-network model.

-

The shutting in of unprofitable offshore wells and the requirements for their plugging and abandonment is attracting more attention to what is being done with the associated subsea equipment. The benefits of leaving subsea systems in place vs. recovering them are being considered.

-

A JIP turned the dial closer to achieving all-electric subsea processing with the underwater testing of a subsea variable speed drive in a harsh water environment.

-

Statoil has submitted a long-awaited development plan for what will become Norway’s northernmost development.

-

Obstacles remain to keeping offshore development competitive with its onshore counterpart. Can the industry advance technology at a pace where the subsea segment will see a resurgence?

-

McDermott announced a letter of award for a contract from Reliance Industries for the deepwater KG-D6 subsea field development in the Krishna Godavari Basin.