Well integrity/control

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

This study illustrates the new capabilities, tailored for carbon-dioxide storage applications, of a modeling framework that provides a quantitative, risk-based assessment of the long-term integrity of legacy plugged and abandoned wells.

-

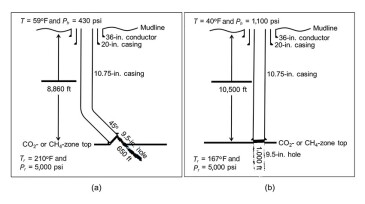

In this paper, a dynamic multiphase-flow simulator is used to evaluate the effectiveness and suitability of using a subsea capping stack to respond to a CO₂ well blowout.

-

The objective of this paper is to outline the importance of new standards for studying hydraulic sealability of barrier materials, with an emphasis on interface analysis.

-

The authors of this paper describe how deployment of dual-casing cement-bond-logging technology has provided critical insights in real time for decision-making on remedial jobs.

-

Advancements in new technologies and rigorous testing methods have enabled the authors of the three SPE papers featured this year to outline a path forward, offering new possibilities that uphold the core objectives of safety and productivity.

-

The oil and gas industry must balance global energy demands with stricter environmental regulations, particularly in drilling, where risks and complexities are higher. Innovative technologies, like those used in this stuck-pipe scenario offshore Azerbaijan, are key to overcoming these challenges and improving safety, speed, and efficiency.

-

This case study uses distributed temperature sensing (DTS) technology to monitor a cemented and plugged well in the Alaska North Slope, highlighting the versatile potential of DTS in long-term monitoring and establishing a workflow that makes the most of that potential.

-

SponsoredTAQA's PulseEight Secure and SwellStack solutions avoid costly workovers and deferred production by riglessly retrofitting an alternative to failed subsurface safety valves.

-

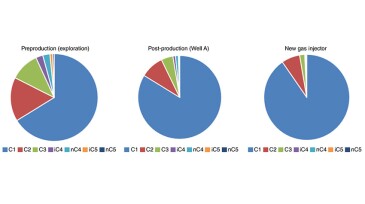

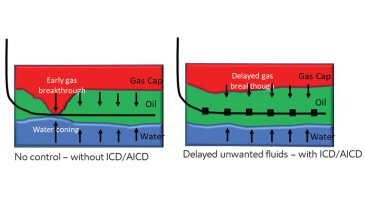

This paper provides insight into designing advanced well completions offshore West Africa with autonomous inflow control devices that enable maximizing the producing life of the wells under various challenging reservoir conditions.

-

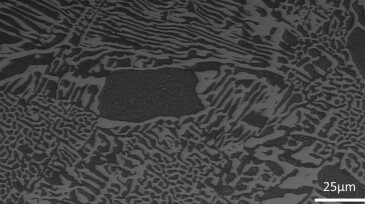

A comprehensive study looks at the sealing efficiency of eutectic bismuth-tin alloy plugs in wells slated for plugging and abandonment through laboratory testing, microscopy analyses, and numerical simulations.

-

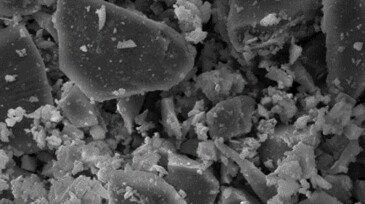

his paper presents research and application of a sustainable, low-density geopolymer alternative to Portland cement for cementing applications in low-temperature wells.