3D printing

-

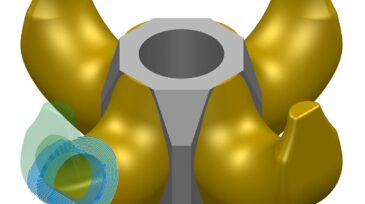

The authors of this paper describe a study in which performance optimization was demonstrated in thermoplastic sealing systems for oil and gas equipment using 3D printing to manufacture multicomponent composite structures.

-

A recent study highlights the major challenges the technology faces as operators consider the pros and cons of using additive manufactured parts in a corrosion-prone environment.

-

This paper describes an approach implemented by the operator to solve research and development challenges by creating in-house infrastructure of both software and hardware.

-

The two companies have entered a commercial agreement in which Baker Hughes will use Oqton’s software to boost its 3D printing capabilities.

-

This paper presents a framework that advances 3D printing in the oil and gas industry, evaluating the challenges this technology is facing in a conservative industry and realizing its potential benefits.

-

The expanded additive manufacturing services widen the companies’ targeted industries to include oil and gas, renewables, maritime, and aerospace.

-

Wind turbine substructures and anchors made of special concrete would float to a site from an onshore plant.

-

The JIPs managed by DNV GL and Berenschot focused on 3D-printed-component certification and supply chain set-up.

-

The hollow hook will weigh close to 1000 kg and have a safe working load of 325 metric tons.

-

Gas turbine blades and large-scale printing machines highlight new advancements in additive manufacturing that are likely to affect the supply chain in the not-so-distant future.

Page 1 of 2