perforations

-

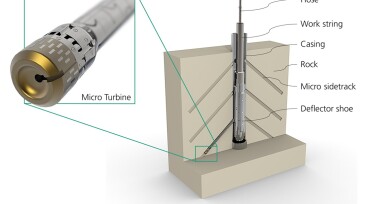

A field test study examines micro turbine drilling in a clay formation that allows steel casing and formation to be drilled in a single operation.

-

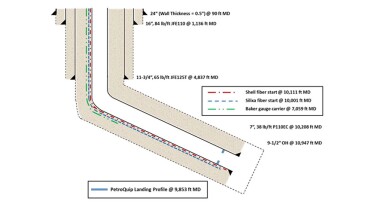

This paper details efforts in 2024 at the Utah Frontier Observatory for Research in Geothermal Energy field laboratory to explore the feasibility of hydraulically fracturing thermally conductive granite formations to create an enhanced geothermal system.

-

SponsoredAs operators strive to increase production under tighter budgets, traditional downhole diagnostics are falling short—too costly, complex, and time-consuming. Seismos Acoustic Friction Analysis (SAFA) offers a smarter, surface-based alternative. This white paper explores how SAFA enables real-time treatment optimization, better fracture performance, and substantial cos…

-

This paper explores the sustainability and safety aspects of laser perforation with a focus on factors such as water requirement, asset integrity, logistics, safety, and surface footprint.

-

In the Marcellus, Repsol is slicing and dicing legacy data to evolve its completions strategy, while in the Permian, ExxonMobil is mastering the 4-mile lateral drillout using lessons learned.

-

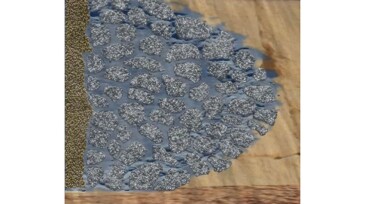

This paper describes a hydraulic fracturing pilot project using a technique that generates higher fracture conductivity to reduce the drawdown during production and improve connection through laminations.

-

This paper presents a case study of a North African oil field producing from two Ordovician sands with differing permeabilities where significant benefit was achieved by fracture stimulating one or both intervals in two wells.

-

This study highlights the strategic implementation of coiled tubing to convey perforating guns in extended-reach wells, overcoming the lockup effect through the deployment of downhole tractors and real-time monitoring tools.

-

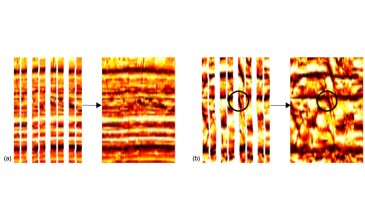

The authors of this paper propose an artificial-intelligence-assisted work flow that uses machine-learning techniques to identify sweet spots in carbonate reservoirs.

-

The trend in fracturing designs has been longer stages with more perforation clusters, which save time and money. But there are a couple of companies testing whether shorter is better for production.

Page 1 of 4