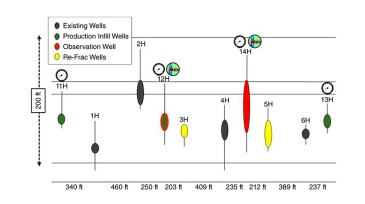

well spacing

-

This paper assesses the potential of augmented depletion development in four US plays: Bakken, Eagle Ford, Midland, and the Anadarko Basin.

-

This paper’s focus is a case study of an Eagle Ford refracturing project in which a range of completion designs were trialed with an approach using offset sealed wellbore pressure monitoring and fiber-optic strain.

-

This paper describes the potential, challenges, and opportunities of using a modified steam-assisted gravity drainage configuration in the Mukhaizna heavy oil field in suboptimal operating conditions.

-

Houston-based Occidental said that one reason it is buying private producer CrownRock is to gain more access to the deep, relatively untapped Barnett formation.

-

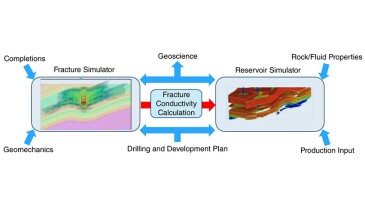

This paper presents a case study of integrated geomechanical and reservoir simulation with a developed fracture conductivity calculation work flow to evaluate well spacing and completions design.

-

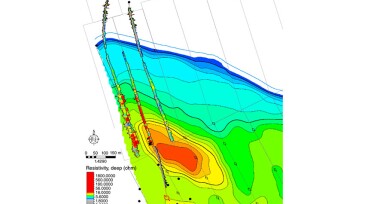

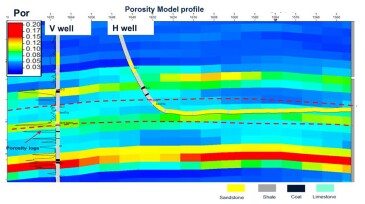

The authors of this paper describe a solution using machine-learning techniques to predict sandstone distribution and, to some extent, automate the process of optimizing well placement.

-

The authors of this paper define a work flow that constrains solutions that match models and field observations and obtains a more-representative model for forecasting and optimizing fracture behavior.

-

This paper presents a numerical simulation work flow, with emphasis on hydraulic fracture simulation, that optimizes well spacing and completion design simultaneously.

-

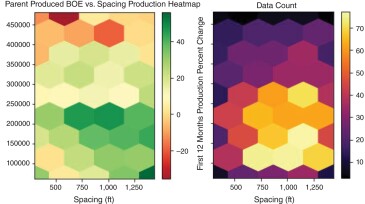

The authors write that child-well performance increases with spacing and decreases with infill timing and that the parent cumulative production at child-well completion is an effective indicator of child-well performance.

-

This paper describes a novel distributed quasi-Newton derivative-free optimization method for reservoir-performance-optimization problems.