well spacing

-

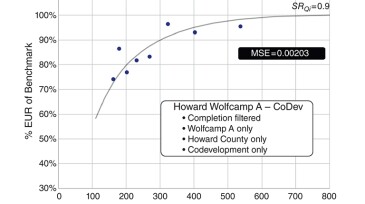

The complete paper builds on existing tools in the literature to quantify the effect of changing well spacing on well productivity for a given completion design, using a new, simple, intuitive empirical equation.

-

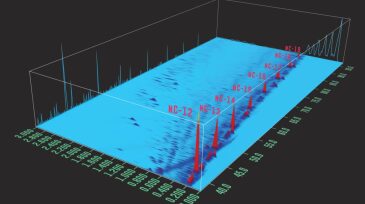

In this paper, the authors describe a model that uses augmented artificial intelligence to optimize well spacing by use of data sculpting, domain and feature engineering, and machine learning.

-

A well-pattern-design work flow proved able to identify substantially better patterns than the traditional approach for a giant mature field.

-

MPD was used to successfully drill through a pore pressure ramp and address a well-control event in conjunction with conventional methods.

-

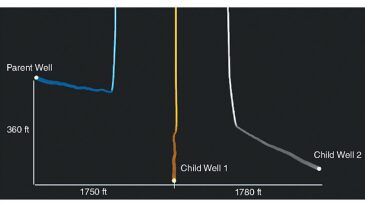

Groups of wells communicate, interfere, and hit each other. It is an unruly scene that can offer benefits. Three stories look at why competing fracture networks can add to the production from rock that might otherwise be missed.

-

Present industry solutions to the challenge of well spacing involve expensive geomechanical Earth modeling or fracture-geometry monitoring that is time-consuming, data-intensive, and geography-specific.

-

In an era where capital markets are hitting the brakes on funding the US shale sector, operators have increasingly pivoted from production growth to maximizing the rates of return via lower-cost wells.

-

In the complete paper, the authors revisit fundamental concepts of reservoir simulation in unconventional reservoirs and summarize several examples that form part of an archive of lessons learned.

-

Proper lateral and vertical well spacing is critical for efficient development of unconventional reservoirs. Much research has focused on lateral well spacing but little on vertical spacing, which is challenging for stacked-bench plays such as the Permian Basin.

-

Knowing which horizon crude oil flows from and in what proportions has been a major challenge for shale producers. Increasingly, they are turning to new technology to find the answer.