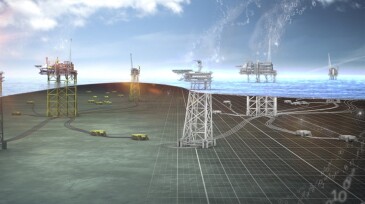

Digital oilfield

This paper presents a multifaceted approach leveraging precise rig control, physics models, and machine-learning techniques to deliver consistently high performance in a scalable manner for sliding.

This paper proposes a novel approach toward drilling maximum-reservoir-contact wells by integrating automated drilling and geosteering software to control the downhole bottomhole assembly, thereby minimizing the need for human intervention.

This paper offers an exploration into the field applications of multiphase flowmeters (MPFMs) across global contexts and the lessons learned from implementation in a smart oil field that uses several types of MPFM.

-

AI can transform our work, but it demands the highest accuracy. Anything less than perfect in oil and gas and other heavy-asset industries is unacceptable.

-

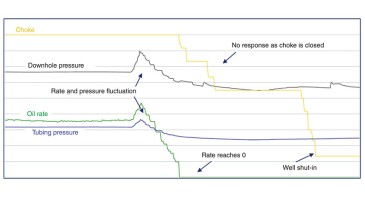

The authors of this paper discuss how intelligent completions in the Gulf of Mexico have allowed for increased production, reduction in operating expenses, enhanced overall reservoir recovery, and improved safety and environmental performance.

-

Digitalization and automation of the drilling process drive the need for an interoperability platform in a drilling operation, where a shared definition and method of calculation of the drilling process state is a fundamental element of an infrastructure to enable interoperability at the rigsite.

-

ExxonMobil developed an automated system to identify nonproductive and underperforming Permian Basin wells and prioritize high-volume wells to return to production.

-

This paper highlights a new online system for monitoring drilling fluids, enabling intelligent control of drilling-fluid performance.

-

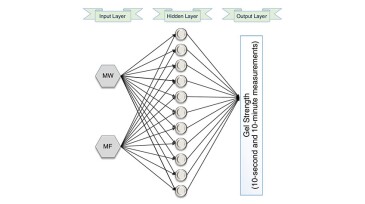

This paper investigates the use of machine-learning techniques to forecast drilling-fluid gel strength.

-

There is no shortage of quantum technology applications in the upstream industry, from supply chain to well placement, making now the time to take it seriously.

-

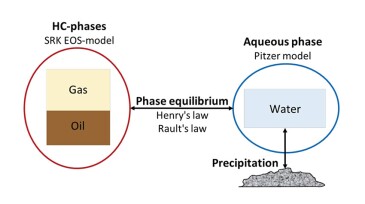

This paper describes the suite of cloud-based digital twin tools that the operator has developed and is integrating into its operations, providing online, real-time calculation of scale risk and deployed barrier health to manage risk on a well-by-well basis.

-

The companies plan to develop new artificial-intelligence-powered processes and workflows to optimize oil and gas production.

-

Aker BP plans to use a software platform from TGS as a process data server designed to improve field operations.