Fracturing/pressure pumping

The paper describes a multientry multistage fracturing technology developed to enable longer laterals, increase stage counts, improve stimulation efficiencies, and derisk operations.

This work demonstrates that a carefully engineered wireline perforation strategy can address the challenges of long-interval high-pressure/high-temperature completions with large intrareservoir-pressure differentials safely and effectively.

This paper describes modeling work performed to design fracturing treatment and spacing for wells in the Project Cape enhanced geothermal system in Utah.

-

The SPE Hydraulic Fracturing Technology Conference and Exhibition is being held 31 January–2 February in The Woodlands, Texas.

-

ProPetro will provide committed services for a 3-year period to an undisclosed Permian Basin operator.

-

This paper presents a numerical simulation work flow, with emphasis on hydraulic fracture simulation, that optimizes well spacing and completion design simultaneously.

-

Recent studies have reignited the question of whether US oil and gas companies are ignoring the opportunity to refracture large swaths of maturing assets.

-

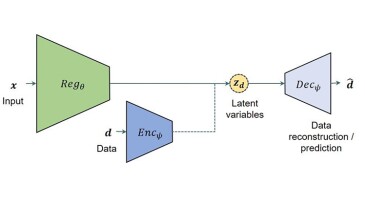

The authors discuss the development of a deep-learning model to identify errors in simulation-based performance prediction in unconventional reservoirs.

-

The authors of this paper compare case studies from the Bakken and the STACK plays to conclude that mineralogy, petrophysics, and reservoir-condition differences between basins cause differences in the effect of fracture-driven interactions.

-

Hydraulic fracture stimulation is proven to be the economic way to develop tight unconventional reservoirs. From an operational perspective, hydraulic stimulation is well established and widely applied to most unconventional plays. There is still room for improvement, however, to increase the efficiency and deepen the understanding of the detailed mechanism in the pro…

-

When Occidental Resources switched to bigger fracture designs to produce more oil, it produced more water as well. Based on research done since, they cannot have one without the other, and at the oil prices recently seen, that’s OK.

-

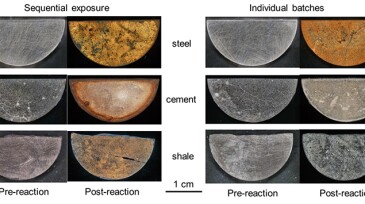

The authors of this paper demonstrate that future produced-water management and scale-mineral control may need to consider the sequential exposure effect of steel, cement, and shale on fluid chemistry and mineral precipitation.

-

Pennsylvania children living near unconventional oil and gas developments at birth were two to three times more likely to be diagnosed with leukemia between the ages of 2 and 7 than those who did not live near this oil and gas activity, after accounting for other factors that could influence cancer risk, a novel study from the Yale School of Public Health finds.