Fracturing/pressure pumping

Modern completions often are equipped with downhole measurement devices that provide critical real-time data not only during the hydraulic fracturing treatment but also during the ensuing production phase.

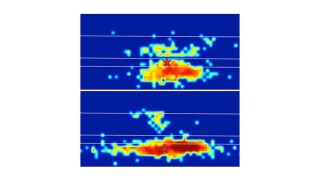

In this work, microseismic observations are integrated with strain and other observations to investigate the microseismic response in relation to the underlying hydraulic fracture geometry for different rock types.

This work proposes a method to interpret far-field strain-change and pressure data to quantify fracture connectivity and properties at the cluster level.

-

The forces of low oil prices and new efficiency trends are converging to remake the US pressure-pumping business into one that can complete more wells with less horsepower than ever. However, that might also mean service provider margins remain low for much of this new decade.

-

The investment group Wilks Brothers, now owners of Carbo Ceramics, has sought stakes in other OFS companies this year.

-

Why stimulate horizontal wells one by one when they can be done two at a time? The largest pressure-pumping company in the business says it might even be possible to complete three wells at once.

-

The contraction of the shale sector and its operations such as drilling and completions due to COVID-19 and the drop in oil price has sifted down to the frac sand suppliers.

-

In an era where capital markets are hitting the brakes on funding the US shale sector, operators have increasingly pivoted from production growth to maximizing the rates of return via lower-cost wells.

-

Carbon dioxide (CO2) waterless fracturing uses liquid CO2 to replace water as the fracturing fluid in reservoir stimulation. The continuity and reliability of the blender are key factors determining performance of the operation.

-

New report offers guidelines for pressure pumpers of the future.

-

As wells across the US shale sector are brought back onto production, they may want to do so strategically to learn about the connectivity of their wells. One challenge will be in selecting a model that delivers the most insight.

-

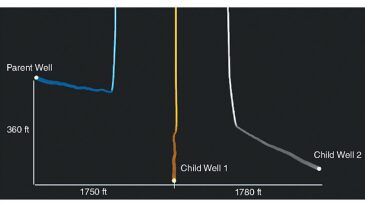

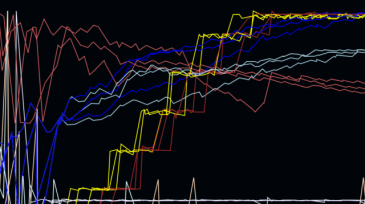

Developed by the large shale producer, its new way to monitor interactions between horizontal wells is now available as a commercial software. The concept is considered a stepping stone toward real-time fracture design.

-

The new software enables high-resolution, real-time fracture-stage data to be shown on top of multiple previous stages to visualize optimized performance or to be tracked against an ideal preset stage.