Fracturing/pressure pumping

Modern completions often are equipped with downhole measurement devices that provide critical real-time data not only during the hydraulic fracturing treatment but also during the ensuing production phase.

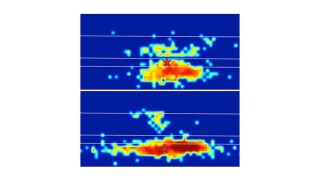

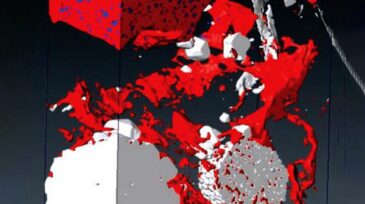

In this work, microseismic observations are integrated with strain and other observations to investigate the microseismic response in relation to the underlying hydraulic fracture geometry for different rock types.

This work proposes a method to interpret far-field strain-change and pressure data to quantify fracture connectivity and properties at the cluster level.

-

In the complete paper, the authors derive a novel analytical solution to model the temperature signal associated with the shut-in during flowback and production periods.

-

A new real-time-visualization (RTV) technology combined with high-resolution pressure reading and acoustic sensors is being used to overcome operational difficulties and to optimize stimulation efforts by reducing uncertainty.

-

This paper describes a smart-tracer-portfolio testing and design solution for multistage hydraulic fracturing that will, write the authors, enable operators to reduce operating cost significantly and optimize production in shale wells.

-

The complete paper demonstrates the benefits of honoring data measurements from a multitude of potential sources to help engineers do a better job of including more diagnostics into routine operations to provide additional insight and result in improved models and completion designs.

-

As operators feel the pinch of low oil prices, so, too, do their service providers.

-

Though they have been a niche ever since their introduction to the market a few years ago, e-fleets are proving to be some of the most downturn-proof assets in the shale sector.

-

The cementing services market size in the US is expected to drop 50% year-on-year from 2019. The significant drop in Permian Basin activity will account for 40% of the total market size reduction.

-

Faster drilling speeds have become one of the major obsessions of the shale sector in recent years. But since completions represent up to 70% of a new well’s cost, maybe this side of the business needs more attention now.

-

The room for error and cost overruns just got a lot smaller with the escalating need to make operations more efficient and leaner with fewer resources and investors continuing to prioritize ESG alongside profitability.

-

While many shale producers are racing to cut costs by removing crews from the field, ExxonMobil and Chevron stood out as maintaining large numbers of fracturing crews.