Fracturing/pressure pumping

Major increases in hydrocarbon production require both incremental and revolutionary technologies, industry leaders said during the SPE Hydraulic Fracturing Technology Conference.

Technology developers expect the tight-oil industry to give lightweight proppants another look after the Permian Basin’s biggest operator becomes an adopter.

In this third work in a series, the authors conduct transfer-learning validation with a robust real-field data set for hydraulic fracturing design.

-

Fracture monitoring to optimize fluid volumes and designs remains a critical area of development. Research is ongoing with the focus on combining different monitoring technologies including tracers, fiber optics, downhole cameras, and microseismic monitoring.

-

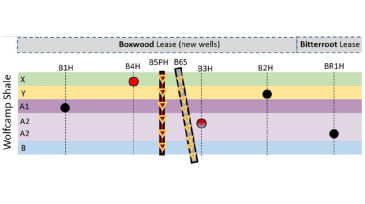

This paper describes efforts at the Hydraulic Fracturing Test Site 2 to collect a research data set to improve understating of spatial and temporal hydraulic fracture dimensions, proppant distribution, and reservoir depletion.

-

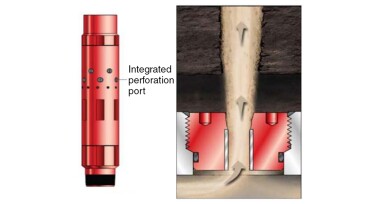

The authors describe a casing-leak-repair alternative to allow continued hydraulic fracturing of an unconventional formation.

-

In this paper, a comparison is presented of the range of production outcomes for Clair Phase 1 and Clair Ridge, including the potential downsides of relying on natural fractures.

-

The mid-sized completions service provider is betting that automation will boost the competitiveness of natural gas-powered pumps.

-

Geologists have identified a formation with a world-changing potential for carbon dioxide storage, but some engineering is required.

-

Service company Liberty Energy has announced the formation of Liberty Power Innovations which will specialize in compressed natural gas.

-

The large US shale producer has officially entered into the renewable energy sector with its largest venture investment yet.

-

Two US test sites have fractured hot, dry rock with plans to create a network of fractures for water heating. They will soon find out if the fractures worked as expected.

-

This article presents a new data-driven analysis to locate low-frequency seismic sources, referred to as near-infrasound or infrasound sources. Combining these infrasound signals with microseismicity signals allows for better characterization and monitoring of the stimulated reservoir volume.