Oilfield chemistry

A new tubing-conveyed tool combines wellbore cleanout with multi-tracer deployment for production diagnostics and reservoir monitoring.

This paper describes a decision-support system that integrates field data, system specifications, and simulation tools to quantify system performance, forecast operational challenges, and evaluate the effect of system modifications in water management.

This paper demonstrates that high-purity salts of calcium, magnesium, strontium, sodium, and lithium can be recovered from produced-water brine using a chemical-reaction pathway followed by vacuum-driven crystallization and a lithium-extraction process.

-

A study done to find the root cause of coiled tubing string failures in Montney indicated microbial-induced corrosion, leading the CT service provider to create a biocide treatment program.

-

Production engineers are often asked to manage both the artificial lift (AL) system and the upstream chemical injection program for a project.

-

Chemical sand consolidation works by pumping chemicals downhole to strengthen the formation and stop sanding. In most cases reported in the industry, chemical consolidation has been used in short production intervals (less than 100 m).

-

Rigless coiled-tubing-unit (CTU) interventions can be effective in returning to production wells that have lost electrical-submersible-pump (ESP) efficiency because of organic, inorganic, or mixed scale deposits.

-

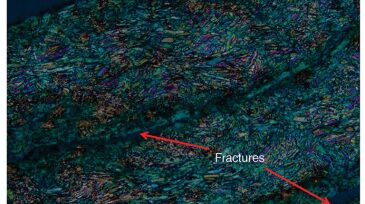

Calcium sulfate (CaSO4) in the form of gypsum and anhydrite is one of the more prevalent evaporite minerals typically found in the carbonate rocks of the western Canadian sedimentary basin (WCSB).

-

The removal of mineral scale in the oil field is typically perceived as a somewhat nonscientific discipline.

-

Sour gas is being produced from a number of carbon-steel-completed wells in the US, Canada, France, and Saudi Arabia.

-

This work introduces sodium gluconate as an efficient and environmentally friendly iron-chelating agent.

-

This feature takes a look at the work being done by companies to improve corrosion inhibitor fluids and inhibition techniques for offshore projects.

-

The development and upgrade of mature facilities is ultimately driven by the significant shift in the composition of the arrival fluids, mainly the increasing water cut and solids production.