Processing systems/design

The $100-billion project is widely considered the largest unconventional development outside of the US and is noted by Aramco as the largest nonassociated gas development in the kingdom.

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

Delfin Midstream announced advancements in partnership with Samsung Heavy Industries and Black & Veatch. By re-purposing existing offshore pipelines and building the FLNG vessels at Asian shipyards, the total capital costs are projected to be around $500–550/tpa.

-

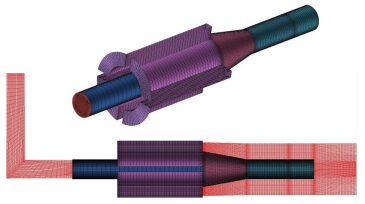

Take a closer look at heat exchangers, including the various types and designs available, applications, and selection considerations. This article helps the project engineer, who is not an equipment specialist, to check that economical choices are made across all involved disciplines.

-

Construction for the field’s second processing platform begins on the same day the Norwegian authorities approved the plan for development and operation for the biggest field development on the Norwegian continental shelf.

-

More flexible approaches to financing, production, and trading are crucial to meeting world’s needs, new study finds.

-

Hydrocarbon processing and treating systems often require large and elaborate surface facilities. When operating in challenging locations, such as deep water or the Arctic, these systems can be expensive. This paper discusses a new adsorption-based gas-separation technology platform.

-

Reducing a separation system’s footprint while increasing separation efficiency is demonstrated in an Oklahoma field trial.

-

Process design of separation internals is just one step in improving the vessel performance. Just as important are the support design and installation steps. These lessons learned help to guide good off- and on-site planning to minimize separator turnaround.

-

The specification and selection of equipment is the responsibility of the static equipment engineer, based on requirements specified by other disciplines, including process, materials, and plant layout. These guidelines contain cost-effective recommendations for design, materials, and fabrication.

-

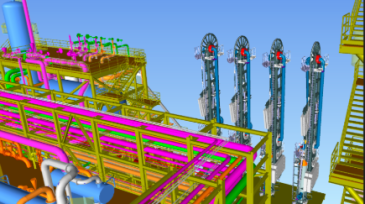

Steady-state modeling of an asset requires the work of multiple engineering teams, which often leads to suboptimal facility design. An integrated model using information consistently across the entire asset may alleviate the pain resulting from conventional methods.

-

A demonstration project of carbon capture, utilization, and storage through enhanced oil recovery was conducted in Saudi Arabia. Surface facilities for such projects are expensive to build and involve tradeoffs in options based on economics for a given set of conditions.