Processing systems/design

The $100-billion project is widely considered the largest unconventional development outside of the US and is noted by Aramco as the largest nonassociated gas development in the kingdom.

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

Troubleshooting and solving separation problems takes a combination of analytical tools, experience, and a knack for investigation. These 5 lessons provide a starting point for assessment.

-

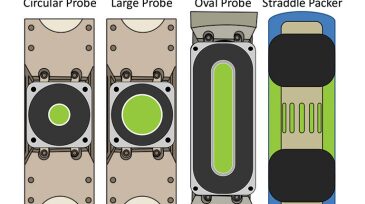

This paper bridges the gap between operational petrophysicists and FTS specialists, introducing an automated work flow by which petrophysicists can conduct FTS jobs.

-

The latest entrants to tackle the development of barrier-fluid-less subsea pumps are Saipem and Curtiss-Wright Corp., who agreed to collaborate in designing and building pumps for water treatment and injection.

-

Oversizing a separator ensures meeting the life cycle needs of a facility, but are we setting ourselves up for failure in the long run? With peak rates typically being short-lived at best, or at worse, well beyond actual production rates, more weight needs to be given to the tail-end of production.

-

Learn about the guidelines for early stages of projects and a method for evaluating the effect of inlet piping and devices on gas/liquid separator performance and useful tools to evaluate the adequacy of a proposed design. [Note: Updated on 22 May, the article contains a number of corrections.]

-

We don’t include a structure like the Eiffel Tower with separators, pumps, and compressors on the top observation platform in an onshore development plan. And yet, how many jacket platforms are there around the world?

-

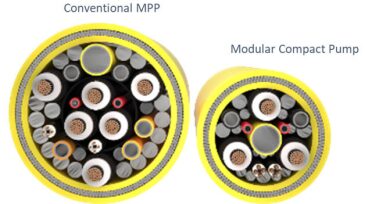

Subsea pumps are used for gas/liquid separation, subsea compression, and subsea boosting. Solutions aiming at cost reductions are crucial to make subsea processing projects feasible. A cost- and complexity-reduction solution for the subsea electrical power supply is a critical consideration.

-

Operator or manufacturer’s reports and published papers are reviewed and a criterion is developed for subsea pump selection.

-

Production from an offshore Angola field has been decreasing because of subsea pressure declines amid water-cut increases and limited gas compressor capacity. The development process leading to the selection of high-boosting multiphase pumps is described.

-

Processing sour natural gas is a challenge. If mercaptans are present in the sour gas, the limited mercaptan-absorption capacity of the well-known alkanolamine solvents can be a problem.