Processing systems/design

The $100-billion project is widely considered the largest unconventional development outside of the US and is noted by Aramco as the largest nonassociated gas development in the kingdom.

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

This paper presents an approach to management and interpretation of pipeline-integrity data, ensuring integrity, safety, and reliability of the operator’s critical pipelines.

-

The Magnus oil field in the North Sea catalyzed a major leap for subsea control systems. The original development of the multiplexed electrohydraulic control system has developed into a multimillion-dollar subsea controls industry.

-

Globally, the International Energy Agency forecasts a recovery in global demand for natural gas in 2021 led by growth in the Asia Pacific region as emerging markets recover. The US will continue to play a significant role as one of the largest producers and contributors to natural gas supply growth.

-

The facility will offer services to design, manufacture, test, certify, and stamp exotic-metal pressure vessels, heat exchangers, and scrubbers. Logan Industries will collaborate with two sister companies in the Netherlands to accommodate workloads.

-

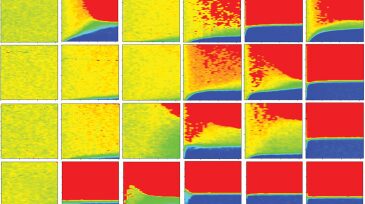

Bottle tests are the preferred method to test petroleum emulsion stability in the industry today. A new technique using nuclear magnetic resonance (NMR) is available to evaluate both stability and demulsification behavior of emulsions.

-

For as long as anyone can remember, the liquid carry-over separation efficiency of 0.1 gal/MMscf has been ubiquitously specified in separator design. This article provides the most likely scenario of its evolution.

-

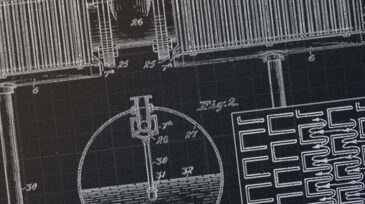

Artificial intelligence systems can be trained to recognize visual content in drawings and provide a simplified context. The complete paper highlights the use of AI to process a scanned drawing and redrawing it on a digital platform.

-

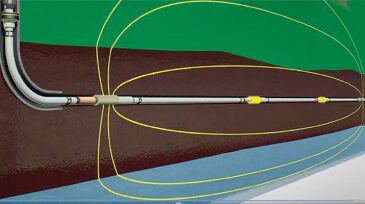

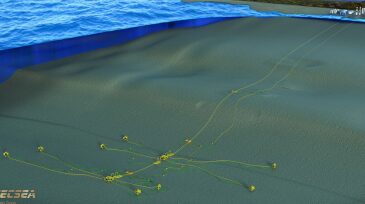

In this paper, the authors introduce a new technology installed permanently on the well completion and addressed to real-time reservoir fluid mapping through time-lapse electromagnetic tomography during production or injection.

-

This case study describes how gas condensates within a subsea tieback system behave very differently to condensed water from a wet-gas system and therefore a pseudo dry-gas system needs to be configured differently for gas-condensate developments.

-

Researchers described the temperature changes at the point where liquid meets the vapor during evaporation. The explanation, developed using the Direct Simulation Monte Carlo method, will allow scientists to more accurately simulate the performance of systems based on the theory of evaporation.

-

Oil and gas extraction using water has opened up new hydrocarbon resources. However they can produce four times more salty water byproduct than oil. Desalination in shale gas and polymer-flood EOR remain niche markets for lowering cost and improving production.