Processing systems/design

The $100-billion project is widely considered the largest unconventional development outside of the US and is noted by Aramco as the largest nonassociated gas development in the kingdom.

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

This study ascertains the capital expenditure and operating expenditure associated with the reuse of existing facilities, specifically regarding a carbon capture and storage project being prepared in South Korea.

-

A system that could help turn stranded-gas fields into producing projects has moved closer to reality, aided by the growing focus on reductions in carbon emissions.

-

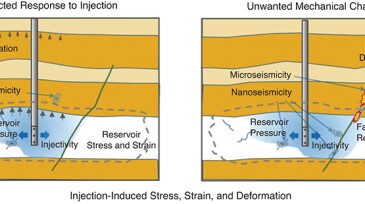

The authors describe an integrated subsurface characterization and monitoring approach for the construction of underground gas storage while ensuring long-term stability.

-

The machine-learning techniques applied aim to deliver a prediction model based on both simulation and real-time field data. The model tracks and monitors system key performance indicators.

-

Being first isn’t easy, as the massive Prelude has demonstrated. Since being commissioned in 2018, the world’s largest vessel has suffered a series of setbacks and has now halted production for an indefinite period of time.

-

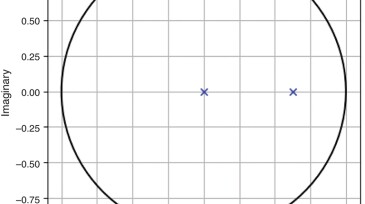

The authors propose a fast, self-learning dynamic process-modeling method that can be used for short-term forecasts, scenario modeling, and process optimization and control.

-

Baker Hughes will build a modular fast-track natural gas liquids processing plant in southern Iraq to capture associated gas for power generation and to reduce flaring.

-

French operator will assist country with enhanced oil recovery, natural gas gathering, and solar projects.

-

The paper focuses on a process developed to identify, evaluate, and eliminate interdependent bottlenecks on the Constitution platform and its flowline network.

-

SwRI’s EZ Flow treatment process is intended to cut down on cost and energy intensity of heavy-crude pipeline transportation.

-

Natural gas is produced from the ground now, but maybe not forever.