Floating production systems

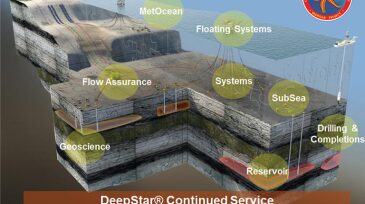

Marking a major milestone as the Gulf of Mexico’s second 20,000-psi deepwater development, the project underscores how advanced high-pressure technology, management of flow challenges, and the floating production system’s role as a regional hub are helping open the door to more Inboard Wilcox development.

Despite a 2.8% drop in liquefied natural gas exports in 2025 because of lost market share in China, Australia anticipates a 2026 rebound as new North West Shelf capacity comes online. Meanwhile, East Coast operators brace for a tsunami of wells entering the decommissioning pipeline and potential energy shortfalls necessitating LNG imports.

Woodside’s $12-billion gas project offshore Western Australia is expected to produce up to 8 mtpa once it’s complete.

-

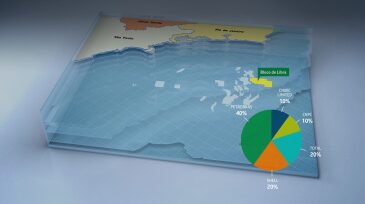

New local content regulations could speed up the pace of presalt oil production by more than 21 billion bbl by the mid-2020s. Karoon and Parnaíba Gás Natural are the first companies to apply to change their contract terms. Petrobras, Shell, BP, ExxonMobil, Petrogal, and Anadarko are also interested.

-

Offshore operators must grapple with ways to keep aging floating facilities on station beyond their original design life.

-

We don’t include a structure like the Eiffel Tower with separators, pumps, and compressors on the top observation platform in an onshore development plan. And yet, how many jacket platforms are there around the world?

-

Shell and SBM Offshore won recognition for their Gulf of Mexico Stones field development. The OTC Distinguished Achievement Award will be presented during a luncheon on 1 May at the Offshore Technology Conference in Houston.

-

The Turritella FPSO (Fig. 1 above) is the deepest floating production system in the world and presented many challenges to successful execution of the surface host facilities.

-

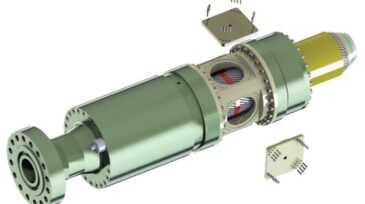

The integrity management of flexible pipes used in subsea production plays a major role in maximizing the availability of the production systems while minimizing safety and environmental risks.

-

ABS granted Approval in Principle to new designs for a floating production storage and offloading hull, a self-elevating unit for a mobile offshore drilling unit, and a tension-leg platform.

-

The long-term decommissioning of the historic Brent field has necessitated redevelopment of the younger Penguins field in the North Sea, where the UK hopes to see more revival projects in the coming years.

-

Applying sufficient passive fire protection (PFP) on topside structural-steel members is critical. Simplified and conservative approaches are available to estimate the extent and amount of PFP necessary.

-

This paper describes a split-process FLNG design where primary production and gas-treatment functions are provided on a host platform while liquefaction occurs on a separate vessel.