Monthly Features

-

This article is the fourth in a Q&A series from the SPE Research and Development Technical Section focusing on emerging energy technologies. In this piece, David Reid, the CTO and CMO for NOV, discusses the evolution and current state of automated drilling systems.

-

Oil and gas experts encourage human/AI partnerships that can “supercharge” capabilities to create competitive advantages.

-

Casing deformation has emerged as a major challenge in China’s unconventional oil and gas fields, prompting the development of new solutions to address the issue.

-

The US supermajor is using one of its lowest-value hydrocarbon products to generate double-digit production increases in its most prolific US asset.

-

The use of real-time wireless downhole pressure gauges proved a valuable alternative to workover operations in two onshore fields in Iraq.

-

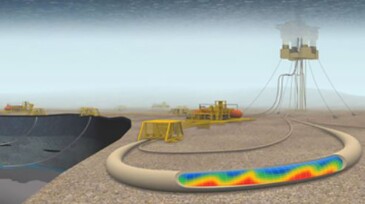

With the right infrastructure and interoperability, subsea resident robotics could unlock more frequent, cost-effective inspections—and a new standard for offshore efficiency.

-

Artificial intelligence is opening new ways to analyze data from microseismic events that occur during hydraulic fracturing. One researcher at Moscow’s Skolkovo Institute of Science and Technology is building a convolutional neural network to get a subsurface view of permeability after fracturing.

-

The oil and gas industry, which had begun showing signs of recovery from a generational downturn, was brought to its knees by the COVID-19 pandemic in 2020. SPE’s technical directors reflect on the pandemic’s impacts and share their outlooks going forward in this annual roundup.

-

Interface Fluidics carved out a niche for itself in the oilfield testing sector a few years ago with a new alternative to coreflooding. Now, along with Equinor, the Calgary-based company is taking on another industry laboratory stalwart: the slimtube test.

-

Innovators at the Norwegian oil company have developed a machine-learning model that analyzes mud-gas data to predict the gas/oil ratio of wells as they are drilled—something that the industry has worked for decades to accomplish.

-

Shell and Tomson Technologies completed field trials in the Gulf of Mexico using new nanoparticle-enabled phosphonate and polymer inhibitors that improve the treatment lifetime of scale squeezes.

-

In striving to boost production of shale gas and tight oil, China is trying enhanced-hydraulic-fracturing technology and real-time data analysis in the Sichuan shale basin. In Daqing’s tight-oil fields, an alternative fracture-completion strategy and post-stimulation flowback technology has been tested.

-

The Houston-based oil and gas company has expanded its footprint in the liquids-rich Permian by more than 550,000 acres.

-

The cutting-edge technological developments in geothermal are devoted to drilling into deeper, hotter, and harder rock. Oil and gas expertise and know-how holds the key to cost reduction.

-

A trio of field studies recently presented at the 2020 SPE Annual Technical Conference and Exhibition highlights in different ways how emerging technology and old-fashioned problem solving are moving the industry needle on proppant and conductivity control.

-

An investigation of casing damage led Chesapeake Energy and Well Data Labs to identify patterns in the treating pressure data that are useful markers when trouble is likely.

Explore Content by Discipline

Power Up With JPT Newsletters

JPT Newsletter (Weekly).

All the top stories, trends, and tech.

JPT Unconventional Insights (Monthly).

Fresh takes on shale and tight oil.

Get JPT articles in your LinkedIn feed and stay current with oil and gas news and technology.