Flow assurance

The objective of this study is to field test a non-nuclear multiphase flowmeter and assess its performance under challenging operating conditions.

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

Experience in subsurface production and lift design is shaping a new generation of geothermal operations built for reliability and scalability.

-

Texas A&M University-Qatar in collaboration with the SPE Qatar Section conducted a 2-day virtual workshop on flow assurance, carbon reduction, and digitalization. Participants included more than 200 professionals associated with academia, research institutes, and industry from 23 countries.

-

Over 1,000 hours of remotely monitored continuous production was achieved on an unmanned platform—a first for standalone offshore solids management in the North Sea.

-

The authors of this paper discuss a biosurfactant treatment that offers an economical method for remediation of formation damage caused by high-molecular-weight paraffin wax deposition in porous media.

-

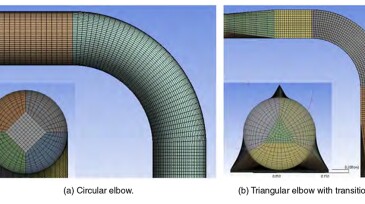

This paper presents a survey of air/water and air/water/sand flow through circular and triangular pipes to study potential effects of triangular pipe geometry.

-

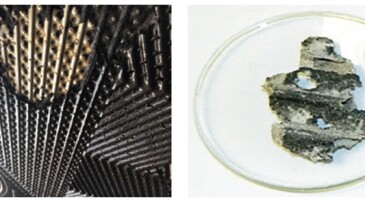

The authors of this paper discuss a robust omniphobic surface treatment material shown to significantly reduce the adhesion of flow-assurance solids.

-

This paper presents software used to understand how foams can alleviate slugging in pipelines.

-

The authors of this paper describe a study of magnesian calcite particles forming hard, inhibitor-resistant calcium-carbonate-like deposits and potential mitigation measures.

-

Flow assurance effects from slugging and various types of solids deposition during engineering, design, maintenance, and operations still create challenging technical issues needing safe, economical solutions. The recurring long-term mitigation of flow assurance phenomena such as the deposition of wax, erosion, asphaltenes, corrosion, and salt, still demands attention…

-

Aramco investigates expanding the use of lasers in the upstream sector of the oil field.

-

This case study demonstrates an estimated cost savings of AICD completions in six wells of more than $20 million in capital and operating expenses compared with a more conventional sliding side door completion to manage gas breakthrough.