Fracturing/pressure pumping

This paper provides an account of the design, implementation, and operational insights from an enhanced geothermal system proppant stimulation targeting a volcanic, dry rock setting with an approximately 330°C bottomhole temperature.

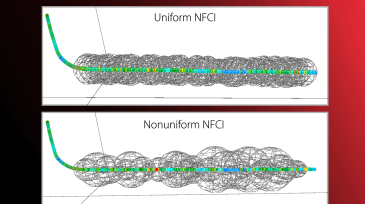

The paper describes a multientry multistage fracturing technology developed to enable longer laterals, increase stage counts, improve stimulation efficiencies, and derisk operations.

This work demonstrates that a carefully engineered wireline perforation strategy can address the challenges of long-interval high-pressure/high-temperature completions with large intrareservoir-pressure differentials safely and effectively.

-

The authors develop a methodology that calculates the mechanical specific energy using real-time drillstring acceleration signals directly.

-

New research from Hess offers compelling evidence that two layers of tight rock can be treated as one and how passive wells can become oil producers.

-

SponsoredAs world demand for energy increases, enhancing the efficiency of oil and gas production is key. Horizontal and multistage fracturing have made a huge difference in recovery. Fracturing fluids have played a key role in these gains—reducing costs and lessening fracture damage. Now fracturing fluids can be more sustainable as well, helping with your company’s ESG goals.

-

SponsoredCase study on how a Marcellus operator was able to recover 99%+ of frac sand in high flowrate wells using advanced cyclone technology.

-

The paper provides information to engineers for selecting high-viscosity friction reducers and describes a methodology for evaluating damage potential and proppant transport.

-

The principles behind unconventional wells lead to production profiles very different from conventional wells. High initial-production rates drop to much lower rates in a matter of months or a few years. How many in the US are currently considered low-production-rate wells?

-

The deal resulted from the exercise of ConocoPhillips’ preemption right to acquire the stake when operator Origin Energy had intended to sell it to US energy investment firm EIG Global Energy Partners for $2.12 billion.

-

The new pressure-pumping company says that its new natural-gas-powered fleet is the most powerful of its kind in the US market and reduces the footprint on well pads by 70% vs. the average diesel fleet.

-

Gazprom Neft and a cloud computing joint venture involving Abu Dhabi National Oil Company have signed an agreement to commercialize jointly developed digital solutions in Russia and the Middle East.

-

SponsoredA novel metric allows operators to chart a new course to maximizing production. Gain greater insight into flow resistance in the near-wellbore region of a fractured well.