Oilfield chemistry

This paper describes a decision-support system that integrates field data, system specifications, and simulation tools to quantify system performance, forecast operational challenges, and evaluate the effect of system modifications in water management.

This paper demonstrates that high-purity salts of calcium, magnesium, strontium, sodium, and lithium can be recovered from produced-water brine using a chemical-reaction pathway followed by vacuum-driven crystallization and a lithium-extraction process.

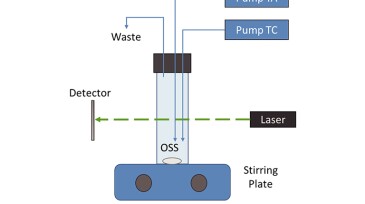

The authors of this paper aim to design, optimize, and evaluate a scalable and energy-efficient plasma-driven advanced-oxidative-process system for produced-water remediation, emphasizing regulatory compliance for safe discharge or reuse.

-

There is a thin line between success and failure of clay stabilizers as they can either drive performance or cause unwanted formation damage.

-

Paraffin deposition on the meters measuring produced water volumes causes inaccurate readings. New technology solutions enable lasting accuracy in the place of routine maintenance that provides a temporary solution.

-

The authors of this paper discuss a biosurfactant treatment that offers an economical method for remediation of formation damage caused by high-molecular-weight paraffin wax deposition in porous media.

-

To evaluate performance of a range of blended inhibitors, a trial was run on a North Sea produced water system which was applying monoethanolamine (MEA) phosphonate-type scale inhibitor as well as novel cleaning programs to counter a high carbonate saturation ratio in the heater. The objective was to find an improved scale inhibitor formulation that would outperform M…

-

The future of the heavy-oil business in Alaska looks more promising than ever after a 2-year pilot delivers technical and economic success.

-

SponsoredCase studies prove the benefits of choosing a greener, more efficient, and more powerful displacement system

-

The authors of this paper develop an assay method to determine effective scale-inhibitor concentration.

-

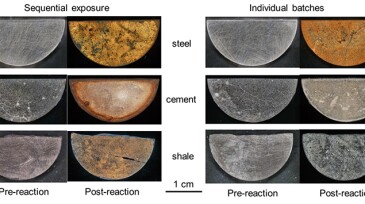

The authors of this paper demonstrate that future produced-water management and scale-mineral control may need to consider the sequential exposure effect of steel, cement, and shale on fluid chemistry and mineral precipitation.

-

This paper highlights a tailored chemical treatment strategy developed for solids mitigation for a Delaware Basin operator.

-

More than 1,000 pieces of oilfield equipment in the US have already been treated with a nanocoating that the company says nixes fouling problems caused by paraffins and inorganic scales.