Oilfield chemistry

This paper describes a decision-support system that integrates field data, system specifications, and simulation tools to quantify system performance, forecast operational challenges, and evaluate the effect of system modifications in water management.

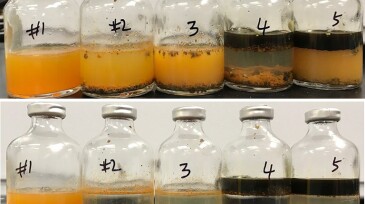

This paper demonstrates that high-purity salts of calcium, magnesium, strontium, sodium, and lithium can be recovered from produced-water brine using a chemical-reaction pathway followed by vacuum-driven crystallization and a lithium-extraction process.

The authors of this paper aim to design, optimize, and evaluate a scalable and energy-efficient plasma-driven advanced-oxidative-process system for produced-water remediation, emphasizing regulatory compliance for safe discharge or reuse.

-

It is pleasantly surprising to find a revival in sandstone acidizing. For many years, sandstone acidizing was becoming almost a lost art, overshadowed by carbonate acidizing and hydraulic fracturing.

-

SponsoredAs world demand for energy increases, enhancing the efficiency of oil and gas production is key. Horizontal and multistage fracturing have made a huge difference in recovery. Fracturing fluids have played a key role in these gains—reducing costs and lessening fracture damage. Now fracturing fluids can be more sustainable as well, helping with your company’s ESG goals.

-

In addition to manufacturing, the facility allows the company to expand its specialty chemicals research and applications for oilfield stimulation and production and better serve the region’s industrial water and process treatment markets.

-

Company will add Molykote lubricants, designed for oilfield use, to its slate of materials offerings.

-

When water and metal meet, you get corrosion. You also get a good dose of creative engineering and innovation.

-

A rigless chemical frac-hit remediation process was designed to address the damage mechanisms of capillary phase trapping, reduced hydrocarbon relative permeability, paraffin deposition, and minor scale deposition.

-

This paper is the second of a two-part series. It covers facilities problems caused by iron, injectivity problems caused by iron, and the mitigation of colloidal iron-related problems.

-

The difficulty in selling a chemical to aid subsea pipeline flow has been delivering it to the wells.

-

Mixing dry polymer powder and water to make friction reducer as needed during fracturing can cut the cost of the additive and the testing of whether a drastically simplified recipe performs as well as more-complex mixes.

-

Friction reducers play multiple critical roles in fracturing. A challenge in selecting the best one for the job is the growing evidence that performance varies, but objective performance measurements are lacking.