Oilfield chemistry

This paper describes a decision-support system that integrates field data, system specifications, and simulation tools to quantify system performance, forecast operational challenges, and evaluate the effect of system modifications in water management.

This paper demonstrates that high-purity salts of calcium, magnesium, strontium, sodium, and lithium can be recovered from produced-water brine using a chemical-reaction pathway followed by vacuum-driven crystallization and a lithium-extraction process.

The authors of this paper aim to design, optimize, and evaluate a scalable and energy-efficient plasma-driven advanced-oxidative-process system for produced-water remediation, emphasizing regulatory compliance for safe discharge or reuse.

-

The effects of aging and temperature on the performance of one-part “just add water” granite based geopolymers are studied for application in well cementing and abandonment. Further studied is the role of zinc as a strength enhancer over a long curing period.

-

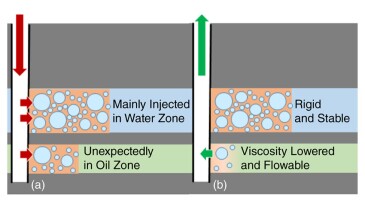

This paper presents the evaluation results of a water-shutoff agent based on an emulsion-type chemical material with nanoparticles.

-

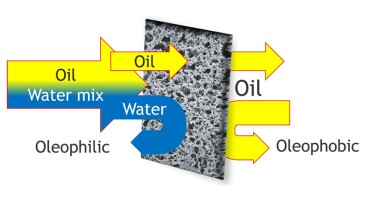

The authors of this paper discuss the use of dissolved polystyrene waste for the preparation of nanomembranes for separation of hydrocarbon pollutants from wastewater streams.

-

The best wells in which to find lithium are in old conventional fields where rusty pump jacks are pulling out mostly water.

-

A new study from Saudi Aramco shows that the answer to the industry's billion-dollar corrosion problem might be sitting in your medicine cabinet.

-

Part 4 of this series provides an overview of ongoing research and recent technology improvements within the US taking place in both academia and the service industry.

-

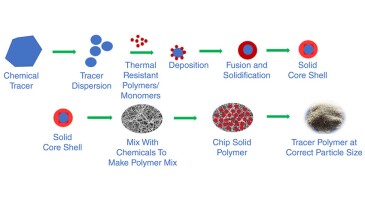

This paper sheds light on newer frontiers of tracer applications with unconventional uses to gain flow insights from an oil and gas reservoir.

-

This paper presents different geochemical approaches to assess the origin of produced gases and thermal maturity and evaluate the effect of adsorption on shale gas during production.

-

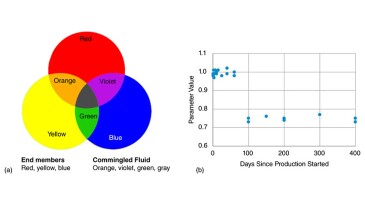

This paper summarizes techniques for production allocation using geochemical methods and describes a best practice for a specialized approach.

-

This paper presents a family of machine-learning-based reduced-order models trained on rigorous first-principle thermodynamic simulation results to extract physicochemical properties.