Separation/treating

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

In this final installment of the Savvy Separator Series (No. 23), the authors present a curated collection of recommended references, articles, and other key resources—a comprehensive guide worth reading, bookmarking, and keeping in your library.

With the right internal modifications, traditional degassers can be enhanced with gas flotation for improved oily water separation. This article outlines key design considerations—including inlet and settling zones, skimming, and solids handling. Two case studies highlight lessons learned in troubleshooting and revamping degasser designs.

-

Troubleshooting and solving separation problems takes a combination of analytical tools, experience, and a knack for investigation. These 5 lessons provide a starting point for assessment.

-

Oversizing a separator ensures meeting the life cycle needs of a facility, but are we setting ourselves up for failure in the long run? With peak rates typically being short-lived at best, or at worse, well beyond actual production rates, more weight needs to be given to the tail-end of production.

-

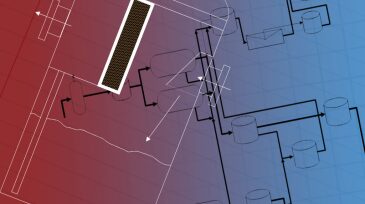

Learn about the guidelines for early stages of projects and a method for evaluating the effect of inlet piping and devices on gas/liquid separator performance and useful tools to evaluate the adequacy of a proposed design. [Note: Updated on 22 May, the article contains a number of corrections.]

-

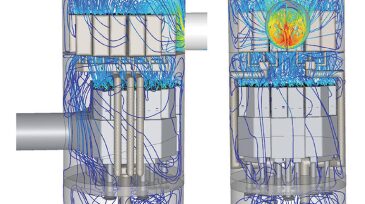

This paper presents details of the retrofit scrubber design and shows the importance of using high-efficiency separation internals.

-

An operator in the western Gulf of Thailand retrofit two partial-processing water-management systems on mobile-offshore-production-unit platforms for bulk removal and treatment of produced water. Water debottlenecking increased oil production by 80% and reduced the infield transfer volume by 62%. Th

-

Large separators are often designed to meet the requirements of higher-capacity facilities. But these vessels bring with them consequences on the operating conditions over the full life cycle of a field.

-

This article highlights some of the code and registration issues the Savvy Separator engineer encounters when retrofitting a vessel with internals to improve or restore the process performance of the separator.

-

Part 2 of this two-part series presents a new methodology for sizing and rating three-phase separators based on quantifying the actual mechanisms and physics that govern separation performance. An example illustrates the calculations needed to achieve the specified outlet fluid qualities.

-

By understanding the factors involved in oil droplet coalescence, the Savvy Separator engineer can assess the operational/chemical factors in the treatment system that are affecting droplet growth and make adjustments to enhance coalescence rates.

-

Operators are increasingly using existing offshore infrastructure for asset life extension, and developing new marginal stranded fields rather than develop new large greenfields. Subsea processing is an enabling technology in this goal.