Separation/treating

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

In this final installment of the Savvy Separator Series (No. 23), the authors present a curated collection of recommended references, articles, and other key resources—a comprehensive guide worth reading, bookmarking, and keeping in your library.

With the right internal modifications, traditional degassers can be enhanced with gas flotation for improved oily water separation. This article outlines key design considerations—including inlet and settling zones, skimming, and solids handling. Two case studies highlight lessons learned in troubleshooting and revamping degasser designs.

-

The complete paper presents a rigorous and consistent method to convert daily separator rates into stock-tank volumes. Recommendations for developing field-specific shrinkage correlations using field test data also are proposed.

-

The newly launched video series featuring speaker Bob Chin, the creator and editor of the OGF Savvy Separator Series of articles, provides a basic level of understanding of separator design and troubleshooting.

-

For as long as anyone can remember, the liquid carry-over separation efficiency of 0.1 gal/MMscf has been ubiquitously specified in separator design. This article provides the most likely scenario of its evolution.

-

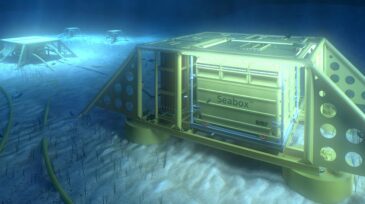

Operators are looking for ways to better handle water coming from subsea wells, which is typically treated at topside facilities. Subsea separation systems are not equipped to discharge water back into the reservoir, so how do companies close the gaps?

-

Virtual metering technology has been in use for years as a cost-effective means of monitoring production, but what else can it do? How reliable is it as a backup to physical multiphase meters?

-

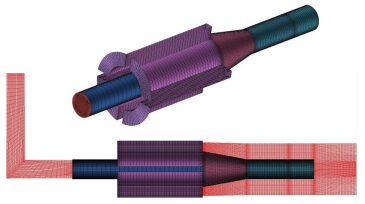

High-fidelity 3D engineering simulations are valuable in making decisions, but they can be cost-prohibitive and require significant amounts of time to execute. The integration of deep-learning neural networks with computational fluid dynamics may help accelerate the simulation process.

-

Hydrocarbon processing and treating systems often require large and elaborate surface facilities. When operating in challenging locations, such as deep water or the Arctic, these systems can be expensive. This paper discusses a new adsorption-based gas-separation technology platform.

-

Reducing a separation system’s footprint while increasing separation efficiency is demonstrated in an Oklahoma field trial.

-

Process design of separation internals is just one step in improving the vessel performance. Just as important are the support design and installation steps. These lessons learned help to guide good off- and on-site planning to minimize separator turnaround.

-

The data collected via monitoring and metering applications are increasingly viewed as central to assessing production performance and in decision making to optimize field development and operations.