Separation/treating

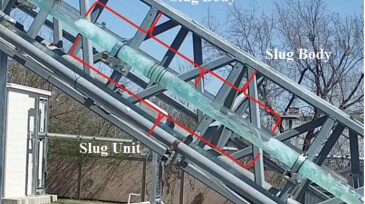

The research facility said it plans to add multiphase-flow-testing capabilities for heavy oil and different viscosities.

In this final installment of the Savvy Separator Series (No. 23), the authors present a curated collection of recommended references, articles, and other key resources—a comprehensive guide worth reading, bookmarking, and keeping in your library.

With the right internal modifications, traditional degassers can be enhanced with gas flotation for improved oily water separation. This article outlines key design considerations—including inlet and settling zones, skimming, and solids handling. Two case studies highlight lessons learned in troubleshooting and revamping degasser designs.

-

Over 1,000 hours of remotely monitored continuous production was achieved on an unmanned platform—a first for standalone offshore solids management in the North Sea.

-

This paper highlights solids-management technologies that are currently available and still in use topside (some of which are potentially outdated).

-

A system that could help turn stranded-gas fields into producing projects has moved closer to reality, aided by the growing focus on reductions in carbon emissions.

-

This selection of papers will familiarize facilities engineers with a variety of topics so they are more prepared for what 2022 may bring.

-

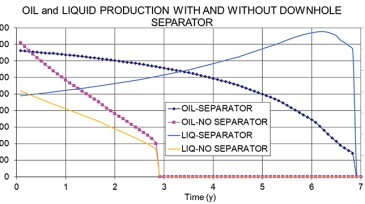

The paper presents a system for separation of water in downhole horizontal wells in which the water produced from the well is not lifted to the surface but reinjected into the reservoir.

-

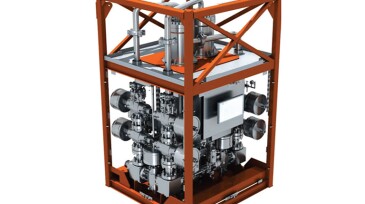

An experimental study of a shroud-type downhole separator for a pumped horizontal or deviated well is presented in this study.

-

This paper is the second of a two-part series. It covers facilities problems caused by iron, injectivity problems caused by iron, and the mitigation of colloidal iron-related problems.

-

A review of the properties of iron compounds and their impact in shale produced water treatment with an emphasis on their colloidal forms. A wide range of problems is associated with these compounds in produced water including emulsion stabilization, oil-coated solids, pad formation in separators, pipeline solids, and plugging of water disposal formations.

-

This 17th article in the Savvy Separator Series addresses how process flow conditions can lead to incorrect or misinterpreted level readings. Poor process vessel design is often exacerbated by miscalibrated instrumentation, leading to suboptimal operation and poor efficiency of the separator. In some cases, the location of the instrumentation can also lead to erroneou…

-

Richard Arntzen, senior process engineer and principal technical expert with Shell, will be presenting an SPE Separations Technology Technical Section Webinar on 22 April.