case study

-

To avoid costly interventions like sidetracking or wellbore abandonment, a check-valve system was installed near the sandface within three injector wells which prevented the mobilization of fines from the reservoir into the wellbore by stopping backflow.

-

Devon Energy along with petroleum engineering consulting and software firm Whitson and cloud computing company Snowflake developed a system to monitor the dynamics of 5,000 wells.

-

Casing deformations are common in the south-west shale regions of China and the Middle East, where the widespread use of 5.5-in., 26- and 26.8-lb/ft casing is the norm. In these regions, the majority of frac plugs are designed with an outer diameter (OD) of 4.055 in. or slightly larger, which frequently encounter restrictions resulting in the loss of bottomhole assemb…

-

An engineered approach to fracture growth in hydraulic fracturing highlights the successful execution of H2S prevention strategies in North Dakota’s Williston Basin.

-

Prior to proceeding with a contract to fulfil a rigless P&A campaign for Sasol in Mozambique, BiSN designed a field trial to prove the effectiveness of its bismuth plug technology. Although the technology had been used in 19 countries by BiSN for a variety of downhole applications, it had not yet been qualified for use in Mozambique.

-

As production dynamics evolve over the full life cycle of a tight-oil play, a single artificial lift method may not be the most cost-effective solution.

-

A new type of skid-mounted production facility was deployed on a pad in Weld County, Colorado, and demonstrated elimination of emissions, improved operational efficiency, and an increased crude yield of 11.3%.

-

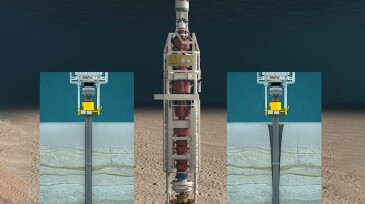

Over a 10-year period, sensors monitoring the motion and loads near subsea wellheads have been mounted on more than 300 drilling campaigns. Integrity parameters were calculated to assess whether subsea conductors provided the intended amount of support during drilling operations. In several of these campaigns, loss of conductor support due to integrity issues was obse…

-

A dissolvable collet field tested in an unconventional completion led to an average running time of 32 minutes per stage in a vertical section and 19 minutes per stage in the horizontal section.

-

Paraffin deposition on the meters measuring produced water volumes causes inaccurate readings. New technology solutions enable lasting accuracy in the place of routine maintenance that provides a temporary solution.