Completions

Malampaya East discovery is estimated to hold 98 Bcf of gas and may help offset declines at the country’s only producing gas field.

For more than a century, LSU has shaped petroleum engineering education, but few assets showcase its impact like the PERTT Lab. With six deep test wells and rare reservoir-depth gas-injection capabilities, the facility is helping drive breakthroughs in well control, carbon-dioxide injection, and next-generation energy technologies.

This study identifies critical knowledge gaps in wellbore integrity and underscores areas that require further investigation, providing insights into how wellbores must evolve to meet the technical demands of the energy transition.

-

SponsoredWith more surface facilities and infrastructure in oil and gas fields, well casing integrity is becoming an even bigger challenge. This article sheds light on the optimum way to deal with the increasing casing integrity challenges in the Middle East through field monitoring and time-lapse casing-integrity and corrosion-inspection logging.

-

This paper outlines issues to be resolved during facility design and provides guidelines, calculations, and examples for sand-handling steps to be implemented after separation.

-

Permian Basin oil wells produce a lot of water. Much of it is injected into disposal zones above and below the basin’s primary oil- and gas-producing zone. When water is injected into these disposal zones, the pressure increases, mainly because no fluid is concurrently removed. Is this increase in pressure a concern? The data would suggest yes.

-

Prior to proceeding with a contract to fulfil a rigless P&A campaign for Sasol in Mozambique, BiSN designed a field trial to prove the effectiveness of its bismuth plug technology. Although the technology had been used in 19 countries by BiSN for a variety of downhole applications, it had not yet been qualified for use in Mozambique.

-

BKV Corp. has combined bullhead and liner refracturing methods to create an approach called the hybrid expandable liner system.

-

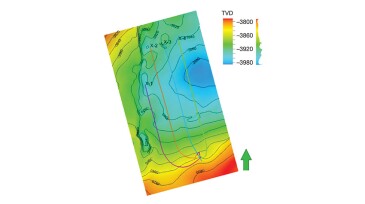

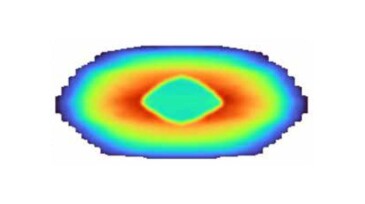

The authors of this paper describe a model-driven work flow developed for hydraulic fracturing design and execution that could be a resource for other shale plays with similar challenges worldwide.

-

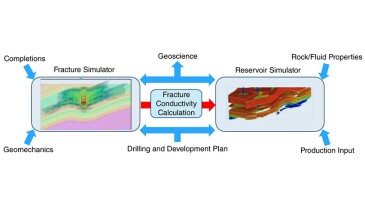

This paper presents a case study of integrated geomechanical and reservoir simulation with a developed fracture conductivity calculation work flow to evaluate well spacing and completions design.

-

The purpose of hydraulic fracture modeling is to improve engineering decision-making. Success requires practical knowledge, engagement with real data, theoretical understanding, and critical thinking. The payoff is tremendous.

-

The authors of this paper write that computationally coupled models enable swift, accurate, and engineered decision-making for optimal asset development.

-

A new study from Saudi Aramco shows that the answer to the industry's billion-dollar corrosion problem might be sitting in your medicine cabinet.