Flow assurance

The authors of this paper describe a project to develop a virtual sensor to monitor the cooling effect downstream of a subsea choke to avoid hydrate plugs during cold-start operations.

Subject-matter experts from industry and academia advanced distributed fiber-optic sensing technologies and their implementation in flow measurement during a special session.

This paper reports the observation of stealth asphaltenes, a potential flow-assurance issue, by means of experimental analysis.

-

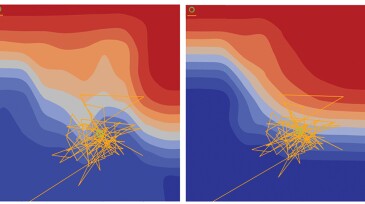

In the authors’ study, a machine-learning predictive model—boosted decision tree regression—is trained, tested, and evaluated in predicting liquid holdup in multiphase flows in oil and gas wells.

-

A review of the properties of iron compounds and their impact in shale produced water treatment with an emphasis on their colloidal forms. A wide range of problems is associated with these compounds in produced water including emulsion stabilization, oil-coated solids, pad formation in separators, pipeline solids, and plugging of water disposal formations.

-

The downtime of manufacturing machinery, engines, or industrial equipment can cause an immediate loss of revenue. Reliable prediction of such failures using multivariate sensor data can prevent or minimize the downtime. With the availability of real-time sensor data, machine-learning and deep-learning algorithms can learn the normal behavior of the sensor systems, dis…

-

The authors present a monoethylene-glycol-sensing system and validate it in a specially constructed flow loop.

-

This paper reviews innovations and technologies used to make the Atlanta field in the Santos Basin a successful case of heavy-oil production in ultradeep water.

-

This paper describes strategies for mitigating asphaltene deposition using fiberglass-lined production tubing and the successful trials thereof.

-

This paper describes the key flow-assurance challenges for a deepwater gasfield development in the South China Sea and the considerations and steps taken to achieve an overall flow-assurance-management strategy.

-

Innovative elements of digitalization and automation of workflows provide a new approach for better handling of slugging in subsea developments with long tiebacks, potentially optimizing production and limiting the amount of flaring.

-

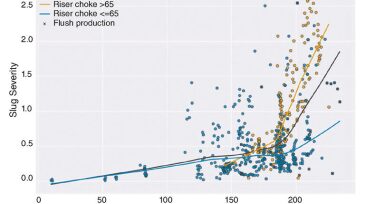

The complete paper presents a set of two- and three-phase slug-flow experiments conducted in a 766-m-long, 8-in. pipe at 45-bara pressure.

-

The complete paper discusses the successful application of a data-driven approach to analyze production data and identify root causes of slugging in a subsea production system on the Norwegian Continental Shelf.