This is the third of a series of six articles on SPE’s Grand Challenges in Energy, formulated as the output of a 2023 workshop held by the SPE Research and Development Technical Section in Austin, Texas.

Described in a JPT article last year, each of the challenges are discussed separately in this series: geothermal energy; net-zero operations; improving recovery from tight/shale resources; digital transformation; carbon capture, utilization, and storage; and education and advocacy.

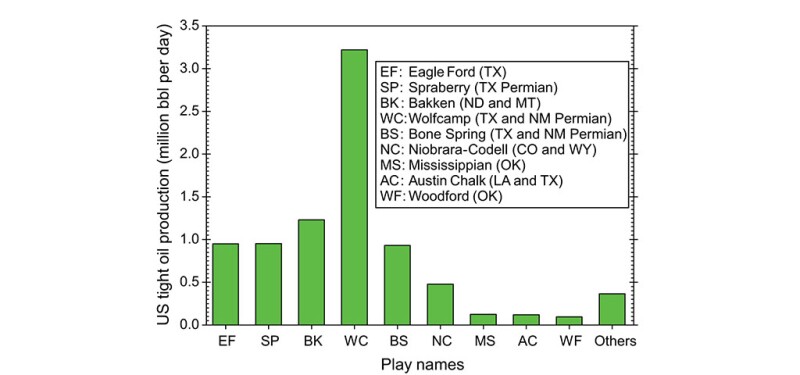

The exploration and extraction of hydrocarbons from tight or shale formations have revolutionized the global energy landscape, unlocking vast oil and gas reserves previously considered inaccessible. According to estimates, substantial oil production has been reported for various tight plays in the US in 2024 (Fig. 1).

However, the production process in tight or shale formations is not without its own set of challenges ranging from technological hurdles to environmental concerns. Therefore, understanding the current outlook is essential for stakeholders to navigate the complex terrain.

To address the significant issues outlined by SPE in July 2023 (Halsey et al. 2023), this article intends to explore the complexities of hydrocarbon extraction from tight and shale reservoirs.

Description of Tight/Shale Formations

First, we present a succinct description of tight or shale formations. Tight or shale oil and gas are hydrocarbons found in oil-bearing mudstone, and shale gas is produced from gas shale or associated with tight oil (Boak and Kleinberg 2020). Tight unconventional formations are characterized by the presence of fine-grained sedimentary rocks that are high in organic matter, such as shale, where hydrocarbons are firmly embedded within the rock matrix.

Challenges in Tight or Shale Oil Production

The Existence of Complex Geometry. Tight and shale formations are known for their complex geological structures, which can make it difficult to predict the distribution and behavior of hydrocarbons within the reservoir. Additionally, shale formations can exhibit significant variability in their thickness, composition, and the occurrence of natural fractures. Hence, it is crucial to understand and navigate the intricate geology of unconventional shale formations to achieve successful shale oil production (Jiang et al. 2016).

Ultralow Reservoir Permeability. The low permeability of tight formations restricts the flow of hydrocarbons, necessitating techniques such as hydraulic fracturing to create artificial pathways for extraction. However, the effective stimulation of fractures requires the use of cutting-edge drilling and extraction methods, such as multistage hydraulic fracturing (fracking) and horizontal drilling, which in turn require precise engineering and a thorough understanding of reservoir characteristics (Pokalai et al. 2015).

Environmental Concerns. The consequences of shale and tight hydrocarbon extraction on the environment have been the subject of intense debate and are a crucial factor in assessing the potential for oil production from shale formations. These issues include water pollution, air pollution, seismic activity triggered by human activities, destruction of natural habitats, and the release of greenhouse gases into the atmosphere. To achieve responsible and sustainable shale oil production, it is crucial to adhere to strict regulations, implement best practices, and conduct research on cleaner extraction technologies.

Thus, the negative effects of shale oil production can be minimized (Absar et al. 2018). The use of gases, including CO2, offers several advantages. One of the benefits is that it allows for efficient storage of injected gas within geological formations. This is due to the gas's ability to remain trapped within the formation, which helps decrease the overall net CO2 emissions. Nevertheless, CO2 gas is typically released into the atmosphere until the stream comprises only pure natural gas, which raises environmental concerns (Burrows et al. 2020).

Water Management. The hydraulic fracturing procedure entails injecting copious amounts of water, combined with proppants and chemicals, into the reservoir to create fractures and maintain them open. The management of water sourcing, treatment, and disposal poses significant logistical and environmental difficulties, especially in regions where water scarcity is a prevalent issue (EIA 2019).

Fiscal Viability. Although technological advancements have made it possible to extract hydrocarbons from tight or shale formations, the process can still be economically challenging, particularly in areas where commodity prices are low or operational costs are high. The expenses incurred for shale oil production include drilling and completion costs, infrastructure development, and operational expenses. These expenses can be influenced by various factors, including the location of the formation, the depth and intricacy of the wells, and the availability of skilled labor and equipment (Kaiser 2012; Aguilera 2014). Moreover, the global market price of oil is a crucial factor in determining the viability of shale oil production.

Nonetheless, advancements in technology have made shale oil extraction more efficient and cost-effective. As a result, the prospects for oil production from shale in the US have improved, as evidenced by the significant increase in shale oil production in recent years (Fig. 1). Therefore, continuous improvement in production efficiency and cost reduction through innovation and optimization are essential for the long-term viability of these projects.

Uncertainty in Governmental Regulations. Tight and shale production operate under a regulatory framework that may change, thereby influencing various aspects, such as permitting procedures, land access, environmental compliance, and taxation policies. The uncertainty associated with potential future regulatory changes, such as climate policies and emission regulations, can make project planning and investment decisions more complex.

Despite this, it is crucial for the government to implement measures and regulations that guarantee sustainable exploitation of shale oil reserves in the US. The implementation of these initiatives can help reduce environmental effects, effectively manage water resources, and tackle the social and economic issues associated with shale oil extraction. They can also offer incentives for research and development of cleaner extraction technologies and promote transparency and accountability in the industry. By enforcing stricter regulations and implementing best practices, the risks posed to the environment and human health can be minimized.

Infrastructure and Logistics. Developing the infrastructure necessary for tight shale hydrocarbon production, such as transportation pipelines, processing facilities, and storage sites, requires substantial investment and coordination. The potential additional expenses and time requirements associated with these challenges could have a significant impact on the profitability and feasibility of shale oil production (Kaiser 2012). Therefore, addressing logistical constraints is crucial for ensuring the smooth operation of extraction projects.

Research, Technology, and Innovation. Although technological advancements have contributed to increased efficiency in tight or shale production, continuous innovation is necessary to tackle technical challenges and unlock the complete potential of unconventional resources. Additional research and development are necessary to enhance the existing drilling methods, reservoir characterization, and other issues stated previously, such as water management practices and environmental performance.

Market and Price Volatility. The hydrocarbon market is often characterized by its unpredictable nature, with prices frequently changing due to various factors such as supply and demand dynamics, geopolitical tensions, and macroeconomic conditions. Market participants often face significant obstacles owing to industry fluctuations. Sudden drops in oil and gas prices can have a significant impact on investment decisions and profitability of tight or shale projects, particularly those with high production costs or financial leverage. These fluctuations pose a major challenge to market participants.

Current Outlook

During the early 2000s, pilot projects were undertaken to improve oil recovery by injecting carbon dioxide and methane gas into tight or shale reservoirs. While chemical-enhanced oil recovery (EOR) techniques such as surfactant and nanofluid injection have been utilized in various formations, they gained widespread popularity only in the late 2010s. The effectiveness of these enhanced recovery methods has been demonstrated in boosting hydrocarbon production in tight formations (Chen et al. 2023).

According to a recent review, a single-well trial conducted in the Middle Bakken demonstrated that the implementation of chemical EOR could lead to a significant improvement in oil recovery. Specifically, a decline curve analysis indicated that this approach could increase the estimated ultimate recovery by up to 25% after 5 years of production and an 8.3% improvement in oil recovery (Chen et al. 2023).

Despite fluctuations in commodity prices and regulatory pressures, production from tight or shale formations continues to grow driven by advancements in drilling and completion technologies. The US, particularly regions such as the Permian Basin and Eagle Ford Formation, remain a hotspot for shale oil and gas production, contributing significantly to global supply.

Operators are increasingly focusing on maximizing production efficiency and reducing costs through technological innovation and operational optimization. Recent advances in horizontal drilling, hydraulic fracturing techniques, and reservoir characterization have improved recovery rates and well economics, thereby enhancing the competitiveness of tight and shale plays.

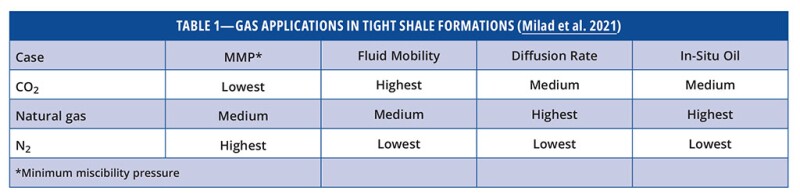

Unconventional oil development involves the application of gas in the huff-n-puff process, which includes various gases, as shown in Table 1.

Although the Permian Basin continues to play a crucial role in tight oil production, it seems that other regions, including the Bakken Formation, Marcellus Formation, and Haynesville Shale, also significantly contribute to hydrocarbon production from tight or shale formations. This diversification of operations helps mitigate risks and presents opportunities for operators to leverage various geological features and market trends. Careful economic analysis and evaluation have shown that the Haynesville Shale play, in particular, has potential for economic viability and sustainability (Kaiser 2012).

Overall, hydrocarbon production in tight and shale formations offers immense potential for meeting the global energy demand, and the prospects for oil production from shale in the US are highly positive and continue to improve with advancements in technology and extraction techniques.

However, it is crucial to address the challenges and limitations associated with shale oil extraction highlighted in this article, such as environmental concerns, water usage, social and economic impacts, and market dynamics. Addressing these challenges requires collaboration among stakeholders, technological innovation, and commitment to environmental stewardship. Consequently, the industry can unlock the full potential of tight and shale formations, while minimizing negative impacts on the environment and surrounding communities.

The US is set to play a crucial role in the future of global energy, as shale and tight resources are expected to make a significant contribution. However, these identified challenges need to be surmounted first.

References

The Tradeoff Between Water and Carbon Footprints of Barnet Shale Gas by S.M. Absar, A. Boulay, M.F. Campa, et al. Journal of Cleaner Production (2018).

Production Costs of Global Conventional and Unconventional Petroleum by R.F. Aguilera, Energy Policy (2014).

Shale Gas, Tight Oil, Shale Oil, and Hydraulic Fracturing by J. Boak and R. Kleinberg, Future Energy (2020).

A Literature Review of CO2, Natural Gas, and Water-Based Fluids for Enhanced Oil Recovery in Unconventional Reservoirs by L.C. Burrows, F.Haeri, P. Sean, et al. Energy & Fuels (2020).

A Comprehensive Review on Screening, Application, and Perspectives of Surfactant-Based Chemical-Enhanced Oil Recovery Methods in Unconventional Oil Reservoirs by W. Chen, X. Geng, W. Liu, et al. Energy & Fuels (2023).

Basic Characteristics and Evaluation of Shale Oil Reservoirs by Z. Jiang, W. Zaixing, C. Liang, et al. Petroleum Research (2016).

Grand Challenges for the Oil and Gas Industry for the Next Decade and Beyond by T. Halsey, G. Agrawal, J.R. Bailey, M. Balhoff, S.J. Borglum, K.K. Mohanty, M. Traver, JPT (2023).

Haynesville Shale Play Economic Analysis by M.J. Kaiser, Journal of Petroleum Science and Engineering (2012).

Huff-n-Puff Technology for Enhanced Oil Recovery in Shale/Tight Oil Reservoirs: Progress, Gaps, and Perspectives by M. Milad, J. Radzuan, A. Sidek, et al. Energy & Fuels (2021).

Management of Oil and Gas Exploration and Production Waste, US Energy Information Administration (2019).

Design and Optimization of Multistage Hydraulic Fracturing in a Horizontal Well in a Shale Gas Reservoir in the Cooper Basin, South Australia by K. Pokalai, Y. Fei, M. Ahmad, et al. The APPEA Journal (2015).

Gideon Dordzie is a post-doctoral Fellow at the Center for Subsurface Energy and the Environment (CSEE) at The University of Texas at Austin. He holds bachelor’s of science and doctor of philosophy degrees in petroleum engineering from the Kwame Nkrumah University of Science and Technology and the University of Wyoming, respectively. Dordzie's primary research areas include conventional and unconventional enhanced oil recovery, nanotechnology, and surface and interfacial science. Dordzie has authored and published several articles in journals, served as a temporary lecturer at the University of Wyoming, and received the 1st place Harry Hill Graduate Excellence Award from the Department of Energy and Petroleum Engineering at the University of Wyoming in 2022 for his outstanding performance in teaching, research, presentations, and publication efforts.

Matthew T. Balhoff is the department chair and a professor in the Hildebrand Department of Petroleum and Geosystems Engineering at The University of Texas at Austin. He holds the Lois and Richard Folger Leadership Chair in Petroleum and Geosystems Engineering and Bank of America Professorship in Petroleum Engineering. He also co-leads the Industrial Affiliate Program on Chemical Enhanced Oil Recovery.

Balhoff became an SPE Distinguished Member in 2017 and is a winner of the 2022 SPE Lester C. Uren Award, 2014 SPE International Young Member Service Award, and 2012 SPE International Teaching Fellow Award. He has 96 peer-reviewed publications and 39 conference papers in the areas of enhanced oil recovery, carbon storage, unconventional resource production, and fundamental processes of flow and transport through porous media.

He holds BS and PhD degrees in chemical engineering from Louisiana State University.