Monthly Features

-

This article is the fourth in a Q&A series from the SPE Research and Development Technical Section focusing on emerging energy technologies. In this piece, David Reid, the CTO and CMO for NOV, discusses the evolution and current state of automated drilling systems.

-

Oil and gas experts encourage human/AI partnerships that can “supercharge” capabilities to create competitive advantages.

-

Casing deformation has emerged as a major challenge in China’s unconventional oil and gas fields, prompting the development of new solutions to address the issue.

-

The US supermajor is using one of its lowest-value hydrocarbon products to generate double-digit production increases in its most prolific US asset.

-

The use of real-time wireless downhole pressure gauges proved a valuable alternative to workover operations in two onshore fields in Iraq.

-

Bad vibes are being addressed by contractors as operators push to go faster, deeper, and longer with unconventional wells.

-

Expectations of continued USD 100/bbl of oil were shattered by a sharp price drop last year that eventually halved the prices of benchmark crudes. Prices were still sinking at the start of the year to lows not seen since 2009 due to a global oversupply of oil.

-

Saudi Aramco’s upstream strategy aims to implement the intelligent field concept in all of its upstream operations by 2016–2017 so it can better understand reservoirs and improve efficiency.

-

A sharp decline in oil prices is pushing oil and gas companies to innovate to increase efficiency and prepare to meet the world’s long-term energy needs, panelists said at the International Petroleum Technology Conference (IPTC) held in Kuala Lumpur, Malaysia, in December.

-

Created by the Institute for Energy Technology in Norway in 1979, Olga was the oil and gas industry’s first transient multiphase flow model. A source of national pride, the program has been declared one of the country’s most important innovations in recent decades.

-

In the realm of enabling technologies, multiphase flow modeling has proven to be one of the most important to the oil and gas industry. Without it, nearly all subsea wells would be too costly or dangerous to develop.

-

SPE’s technical directors are focused on problems that require working outside the bounds of their discipline.

-

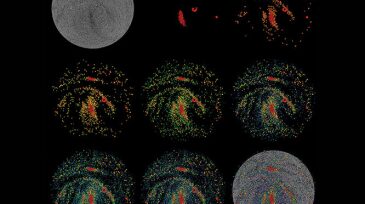

An ongoing research project started nearly 3 years ago by the US Department of Energy’s National Energy Technology Laboratory (NETL) is shedding new light on what really happens to foamed cement as it is pumped deep down offshore wells during completions.

-

The rapid development of shale formations over the past decade has led the United States to become the world’s undisputed leader in natural gas production.

-

Well plugging and abandoning on a limited budget is a lofty goal that forces the industry to consider new ways and new materials. Cost-effectively dealing with this global problem will require developing tools to carry out the decommissioning without bringing in a drilling rig.

-

Making hole has become a more difficult and complex operation as operators move into untapped horizons, especially deepwater and unconventional fields.

Explore Content by Discipline

Power Up With JPT Newsletters

JPT Newsletter (Weekly).

All the top stories, trends, and tech.

JPT Unconventional Insights (Monthly).

Fresh takes on shale and tight oil.

Get JPT articles in your LinkedIn feed and stay current with oil and gas news and technology.