case study

-

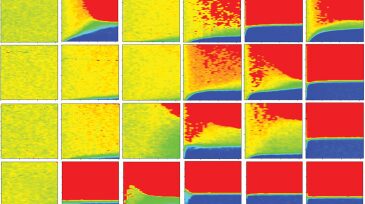

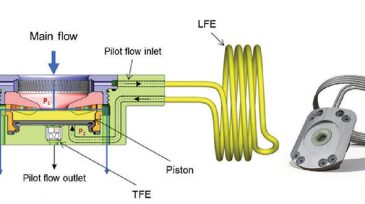

Often it is too difficult to create the fault conditions necessary for training a predictive maintenance algorithm on the actual machine. A digital twin generates simulated failure data, which can then be used to design a fault-detection algorithm.

-

A multizone water-injection project has ultimately proved a method of using intelligent completion interval-control valves in place of traditional sand-control completions in soft sand reservoirs.

-

An intelligent drilling optimization application performs as an adaptive autodriller. In the Marcellus Shale, ROP improved 61% and 39% and drilling performance, measured as hours on bottom, improved 25%.

-

Bottle tests are the preferred method to test petroleum emulsion stability in the industry today. A new technique using nuclear magnetic resonance (NMR) is available to evaluate both stability and demulsification behavior of emulsions.

-

While drilling in deepwater Gulf of Mexico, a topdrive failure forced the shutdown of all drilling operations for the rig operator and lasted for 114 hours.

-

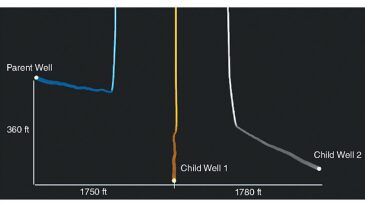

In an era where capital markets are hitting the brakes on funding the US shale sector, operators have increasingly pivoted from production growth to maximizing the rates of return via lower-cost wells.

-

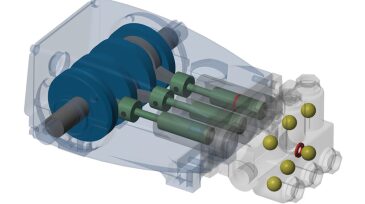

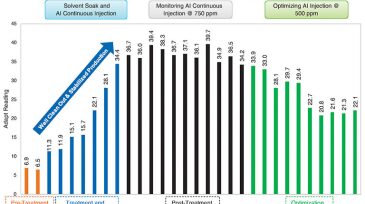

Autonomous Inflow Control Valve technology demonstrates significant benefits within first year.

-

Researchers use novel methodology to measure the thermo-electric properties of native crude.

-

The room for error and cost overruns just got a lot smaller with the escalating need to make operations more efficient and leaner with fewer resources and investors continuing to prioritize ESG alongside profitability.

-

A downhole compressor solution based on advanced magnetic technologies completed its first field trials in an unconventional gas well. It resulted in a 62% increase in gas production and significant increase in liquid production compared to using a rod pump previously in the well